Introduction

Forklifts are a crucial part of the material handling industry, but they can also be dangerous if not used properly. I’ve seen firsthand the importance of forklift safety in the workplace.

Forklifts are a common sight in warehouses, construction sites, and other industrial settings, but they are not without their risks. In the United States alone, there are an estimated 85 forklift-related deaths and 34,900 serious injuries each year, according to the Occupational Safety and Health Administration (OSHA). Forklift accidents can happen due to a variety of reasons, such as operator error, lack of proper training, and failure to follow safety guidelines. That’s why it’s important to ensure that forklifts are operated safely and properly to reduce the risk of accidents and injuries. To that end, in this article, we will be discussing 10 tips for ensuring the safe operation of forklifts. These tips cover a range of topics, from proper safety gear and training, to regular safety inspections, speed limits, and more.

By following these tips, forklift operators can reduce the risk of accidents and create a safer work environment for themselves and their colleagues. It’s essential to keep in mind that ensuring safety and reducing the risk of accidents is a shared responsibility, both employees and employers have to work together to establish a culture of safety in the workplace. Employers should provide proper training and resources to their employees, while employees should follow safety guidelines and best practices.

However, let me first preface this list of tips with what I consider to be one of the most important things you need to remember as a forklift operator, the Forklift Stability Triangle.

The Forklift Stability Triangle

From a physics perspective, one of the most important things a forklift operator must know when using a forklift is how to maintain stability and balance. This is because a forklift is a heavy machine that can easily tip over if not operated properly. The center of gravity of the forklift and the load it is carrying must be kept within the base of support provided by the wheels, if the center of gravity of the load is too high or too far to one side, the forklift can tip over. To maintain stability, the operator must be aware of the weight distribution of the load and the position of the center of gravity. This means that the load should be placed as close to the forklift as possible, and the weight should be distributed evenly on the forks. The operator should also be aware of the weight capacity of the forklift and the weight of the load they are lifting to avoid overloading it. Additionally, the operator should avoid sharp turns and sudden movements, which can cause the forklift to tip over. It’s also important to keep in mind that the stability of a forklift is affected by the surface it is operating on. Uneven surfaces, slopes or wet or slippery conditions can make it harder to maintain stability. The operator must be aware of these conditions and adjust their driving and loading accordingly.

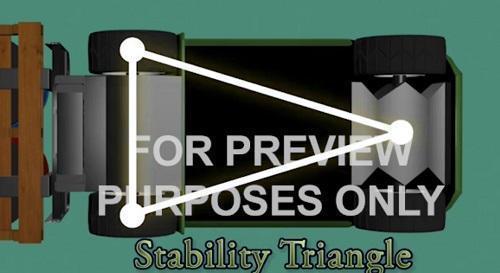

One of the most useful training tools that organizations use to teach their employees about using forklifts safely is the concept known as the forklift stability triangle.

This triangle is a visual representation of the three factors that affect the stability of a forklift: the load, the center of gravity, and the base of support provided by the wheels. The triangle helps the operator remember the physics involved in operating a forklift, as it illustrates how these three factors interact and how changes in one can affect the others. The load represents the weight of the item being lifted and its position on the forks. The center of gravity represents the point at which the weight of the load is evenly distributed. The base of support provided by the wheels represents the area on which the forklift is in contact with the ground. The operator must keep the center of gravity of the load within the base of support provided by the wheels. If the center of gravity is too high or too far to one side, the forklift can tip over. The load should be placed as close to the forklift as possible, and the weight should be distributed evenly on the forks. The operator should also be aware of the weight capacity of the forklift and the weight of the load they are lifting to avoid overloading it. The forklift stability triangle also helps the operator understand how the surface condition of the ground can affect the stability of the forklift. An uneven surface or a slope can change the base of support provided by the wheels and affect the stability of the forklift. The operator must be aware of these conditions and adjust their driving

10 Practical Tips for Forklift Safety

- Always wear the proper safety gear. This includes a hard hat, safety glasses, and steel-toed boots. Additionally, operators should wear high-visibility clothing to make them more visible to others on the job site. Proper safety gear is essential to protecting forklift operators from injury. Hard hats protect the head from falling objects, while safety glasses and steel-toed boots protect the eyes and feet from impact. High-visibility clothing makes the operator more visible to others on the job site, reducing the risk of collisions. Wearing the proper safety gear is not only required by OSHA, but it is also a best practice for forklift safety.

- Never operate a forklift without proper training. OSHA requires that all operators be trained and certified before operating a forklift. This includes both classroom and hands-on training. Proper training is essential for the safe operation of a forklift. OSHA requires that all forklift operators be trained and certified before they can operate a forklift. This includes both classroom and hands-on training. Classroom training covers the basics of forklift operation, safety regulations, and best practices, while hands-on training allows operators to practice operating a forklift in a controlled environment. Without proper training, operators may not be familiar with the proper techniques for operating a forklift, which can lead to accidents and injuries.

- Conduct regular safety inspections of the forklift. Before using a forklift, check for any damage or malfunctions and ensure that all safety devices are functioning properly. Regular safety inspections are critical to maintaining the safe operation of a forklift. Before using a forklift, it is important to check for any damage or malfunctions, as well as to ensure that all safety devices are functioning properly. This includes checking brakes, steering, lights, and horn, as well as checking for any leaks or damage to the forks or other attachments. By conducting regular safety inspections, operators can identify potential problems before they become accidents, which can help reduce the risk of injury.

- Follow posted speed limits and use caution when turning corners. Forklifts are heavy and can easily tip over if not operated carefully. Speed limits are posted for a reason, and forklift operators should always follow them. Forklifts are heavy and can easily tip over if not operated carefully, especially when turning corners. By following posted speed limits, operators can reduce the risk of tipping over and ensure that they have enough time to react to potential hazards. Additionally, when turning corners, operators should use caution and take the turn slowly to ensure that the forklift stays stable and upright.

- Do not exceed the weight capacity of the forklift. Overloading a forklift can cause it to tip over or become unstable. Exceeding the weight capacity of a forklift can be incredibly dangerous, and it should be avoided at all costs. Overloading a forklift can cause it to tip over, which can lead to serious accidents and injuries. Additionally, overloading a forklift can also make it unstable and difficult to maneuver, increasing the risk of collisions. To avoid overloading a forklift, operators should always be aware of the weight capacity of the forklift and the weight of the load they are lifting.

- Keep the work area clean and free of clutter. This will help prevent accidents and make it easier to maneuver the forklift. A clean and organized work area is essential for the safe operation of a forklift. Clutter and debris can make it difficult to maneuver a forklift, increasing the risk of accidents and collisions. Additionally, clutter can also hide potential hazards, such as obstacles or uneven surfaces, which can lead to accidents To maintain a safe work area, operators should take the time to keep the area clean and free of clutter. This includes keeping aisles and passageways clear, removing debris from the floor, and organizing materials and equipment. Additionally, operators should also be aware of the layout of the work area, including the location of any obstacles or hazards, to ensure that they can navigate the area safely. By keeping the work area clean and organized, operators can reduce the risk of accidents and make it easier to maneuver the forklift.

- Never use a forklift to lift people or place them in an elevated position. This is extremely dangerous and strictly prohibited. Forklifts are not designed to lift people, and it is strictly prohibited to use a forklift to lift or place people in an elevated position. This is extremely dangerous and can lead to serious accidents and injuries. Instead, operators should use proper equipment, such as scaffolding or ladders, to access elevated areas. Additionally, operators should never allow anyone to ride on a forklift, even as a passenger, as this is also strictly prohibited and can lead to serious accidents.

- Always be aware of your surroundings and the people around you. This includes other operators, pedestrians, and other vehicles. Awareness is key to the safe operation of a forklift. Operators should always be aware of their surroundings, including other operators, pedestrians, and other vehicles. This includes being aware of the location of other forklifts and other equipment, as well as the location of pedestrians and other people in the area. Additionally, operators should also be aware of the location of any obstacles or hazards, such as narrow aisles or low ceilings, to ensure that they can navigate the area safely. By staying aware of their surroundings, operators can reduce the risk of accidents and keep themselves and those around them safe.

- Keep a safe distance from the edge of raised platforms, docks, or mezzanines. Forklifts should be kept a safe distance from the edge of raised platforms, docks, or mezzanines to reduce the risk of accidents. These areas can be dangerous due to their elevation and the potential for falls, so operators should always be aware of their proximity to the edge and take care to keep a safe distance. Additionally, operators should also be aware of any safety barriers or warning signs that are in place and make sure to follow them. By keeping a safe distance from the edge, operators can reduce the risk of accidents and injury.

- Always remember to turn off and secure the forklift when it is not in use or if the operator is leaving the area. It is important to turn off and secure the forklift when it is not in use or if the operator is leaving the area. This can prevent accidents and injuries caused by someone else using the forklift without proper training or authorization. Additionally, operators should also make sure that the forklift is parked in a designated area and that the forks are lowered and secured before leaving the forklift unattended. It is also important to follow company’s policy and procedures as well as OSHA guidelines to secure the forklift. By turning off and securing the forklift, operators can help ensure the safety of themselves and those around them.

Conclusion

By following these tips, forklift operators can greatly reduce the risk of accidents and injuries on the job. Remember safety is always the first priority, and it’s the responsibility of every operator to ensure that they and those around them are safe.

—

Does your organization require online safety training for Forklift Safety?

Please be sure to check out the free demonstration of our learning management system for and our online safety training courses for Forklifts:

Forklift/Powered Industrial Truck Safety – Online Safety Training

Forklift Safety: Industrial Counterbalance Lift Trucks – Online Training