Many workers get injured using tripod orchard ladders every year, but these incidents can be prevented. Tripod orchard ladders are the go-to choice for fruit pickers and landscapers. By following a few safety measures, employers can ensure that these workers stay safe and injury-free.

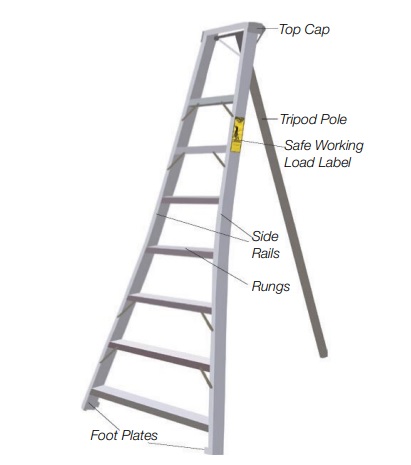

So, what’s a tripod orchard ladder? It’s a portable, self-supporting ladder designed specifically for orchards and landscape maintenance tasks, like pruning and fruit harvesting. This ain’t your regular all-purpose ladder, folks. It has a flared base and a tripod pole that helps it stand strong on soft, uneven ground. And since these ladders don’t have a spreader bar or locking mechanisms, their side rails and tripod pole must slightly penetrate the ground for stability.

Tripod Orchard Ladder Injuries and Hazards

Now, let’s talk about some common tripod orchard ladder injuries and hazards. Sprains, strains, fractures, concussions, and dislocations can all happen while using a ladder, mostly due to overreaching, moving, lifting, or carrying it. Unstable ladders, overextended tripod poles, or slipping can cause falls, and workers can also get injured from being struck by falling ladders. Weather conditions like high winds and ladder proximity to electrical lines can lead to fatalities. Plus, back injuries can occur when carrying the ladder improperly for long periods or distances.

Fall Prevention

So, how do we prevent falls, the most common ladder hazard? More falls happen on the upper part of the ladder than the middle or lower portions. Slippery steps, unstable ladders, and not maintaining proper contact with the ladder are the usual culprits. Employers can prevent most tripod ladder fall hazards by training workers and following these safety measures:

- Secure the ladder firmly in the ground to prevent collapsing, slipping, moving, or falling. Avoid soft spots or holes.

- Position the tripod pole uphill when using the ladder on sloped ground.

- Inspect ladders regularly.

- Teach workers to center themselves between the ladder’s side rails and use both hands when climbing up and down.

- Provide required personal protective equipment, like eye protection, for workers.

- Make sure workers wear non-slip shoes with stiff soles and a good-sized heel.

- Employers should train workers not to overreach beyond the ladder’s side rails.

- The ladder should be moved to perform orchard work.

- Also, avoid overfilling produce bags

- Don’t stand or work on the ladder’s top three steps

- Never move from a ladder onto a tree branch or use the branch for balance.

Tripod Orchard Ladder

General Safety Precautions

Now, let’s talk about some general safety precautions employers should take before work begins:

- Mark dangerous areas for workers to avoid, like trees and electrical lines.

- Establish and enforce ladder safety rules.

- Allow only one worker on each ladder.

- Don’t allow the use of other types of ladders.

- Conduct daily safety talks.

- Choose and use ladders appropriate for worker and tree size.

Carrying, Lifting and Moving Ladders

Workers often carry, lift, and move ladders throughout the workday. To prevent injuries, employers should train workers to properly handle one ladder at a time. Teach workers to:

- Place their arm through the ladder and balance it on their shoulder.

- Carry ladders horizontally with the top facing forward, securing the tripod pole to prevent slipping.

- Use the horizontal position to carry ladders over long distances, either by one or two workers.

- Watch for other people and nearby trees.

Proper ladder lifting and handling techniques can protect workers from back injuries and make their work easier. Employers should remind workers of these techniques throughout the workday.

Training

Training is crucial for both full-time and seasonal workers. Employers should train them to recognize hazards and report unsafe conditions to supervisors immediately. Ladder safety training should be conducted by experienced or knowledgeable individuals, covering ladder maintenance, storage, and how to respond to ladder injuries and incidents.

Ladder safety training should be provided before any worker is allowed to work on a tripod orchard ladder.

Train workers to:

- Never leave a ladder standing open at the end of the workday.

- Limit or reschedule work on ladders during high winds, heavy rain, or thunderstorms.

- Avoid walking under or near ladders in use by using a barrier or having a coworker act as a lookout.

- Never use ladders on hard surfaces.

- Use and carry tools on a ladder safely.

Inspecting, Maintaining and Storing Ladders

Inspecting, maintaining, and storing ladders are essential to ensure their safe use. Before a ladder is used, the employer must inspect it for defects and ensure it’s in good working condition. Employers should focus on:

- Daily ladder checks according to the manufacturer’s guidelines.

- Inspecting ladders for missing, loose, or sheared rivets, broken steps, and bent rails or tripod poles.

- Examining ladders from top to bottom after they tip over, before placing them back in service.

- Remove defective or damaged ladders from service immediately.

- Tag damaged ladders as “out-of-service” and separate them from non-damaged ladders.

- Don’t let workers repair damaged ladders.

- Store ladders according to the manufacturer’s instructions, away from excessive heat and cold.

Emergency Response Procedures

Employers should develop an emergency response plan tailored to their facility and operations. Train workers to call 911 and avoid moving injured workers suspected of having neck or spinal injuries. Provide first-aid and CPR training for workers.

Ladder Safety Checklist

Workers should be trained to use a ladder safety checklist before use. The following checklist (not all-inclusive) identifies inspection requirements for a tripod orchard ladder safety program:

- Rivets/joints and fastenings are in place and secure.

- Steps are in place and secure.

- Steps are free of dents, bends, and damage.

- Ladder is free of rust, grease, or oil.

- Safe Working Load label is attached to the ladder’s side rails.

- Top cap is tightly secured to the ladder’s side rails and tripod leg hinge.

- Tripod leg is intact and not able to bend.

- Tripod leg is free of cracks and dents.

- Footplate is free of cracks and rust.

Workers’ Rights

Workers have the right to…

- Safe working conditions without a risk of serious harm.

- Receive information and training about workplace hazards, prevention methods, and OSHA standards.

- Review records of work-related injuries and illnesses.

- File a complaint asking OSHA to inspect their workplace for serious hazards or employer violations.

- Exercise rights under the law without retaliation, including reporting injuries or raising health and safety concerns with employers or OSHA. Workers must file a complaint with OSHA within 30 days if they’ve been retaliated against.

Conclusion

In conclusion, the safety and well-being of workers using tripod orchard ladders is a critical concern for employers in the fruit picking and landscaping industries. By implementing comprehensive safety measures, providing regular training, ensuring proper inspection and maintenance of equipment, and fostering an environment of open communication, employers can significantly reduce the risks of injuries and incidents associated with tripod orchard ladder use. Empowering workers with knowledge and tools to prioritize safety will not only protect their health but also contribute to a more efficient and productive work environment. Let’s work together to make tripod orchard ladder safety a top priority in the agricultural sector, ensuring a safer and healthier future for all.

For more information, see OSHA’s Workers page, and for additional ATV safety and other farmworker issues, visit OSHA’s Safety and Health Topics Agricultural Operations website.

References: