Introduction

Hydraulic fracturing, commonly known as “fracking,” is a technique used to stimulate oil and gas production from wells. It involves pumping large volumes of water, sand, and chemicals into a well under high pressure to fracture shale formations and improve access to trapped hydrocarbons.

The process is not new, but its use has greatly increased over the past decade with advances in directional and horizontal drilling and multi-stage fracking enabling access to previously unreachable oil and gas deposits. Along with expanded use of fracking come growing concerns over occupational exposures and health hazards for workers at these sites.

In particular, recent National Institute for Occupational Safety and Health (NIOSH) field studies have shown that worker exposure to airborne respirable crystalline silica dust—referred to hereafter simply as “silica”—is a serious health threat to workers conducting certain fracking operations. This hazard alert examines the occupational health hazards associated with fracking, with a focus on exposure to silica dust, its health effects, recommendations to better protect workers, and OSHA/NIOSH assistance available. Increased awareness and proper controls to prevent excessive silica exposure are essential to ensuring worker health and safety.

Understanding Crystalline Silica Risks

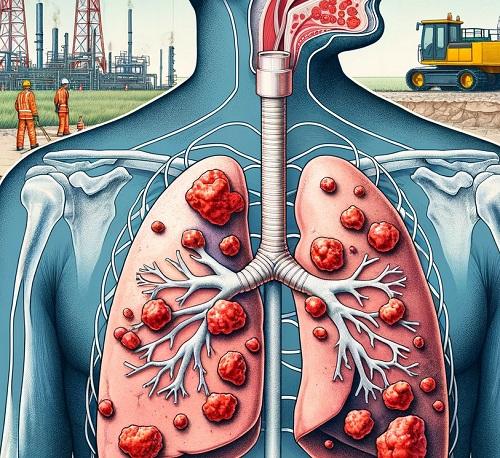

Silica is a common mineral found in sand, clay, stone, concrete, brick, and artificial stone. When inhaled by workers in small respirable sizes, it can lead to silicosis, lung cancer, chronic obstructive pulmonary disease (COPD), and kidney disease.

Respirable crystalline silica refers to particles small enough to go deep into the lungs when breathed in. The Occupational Safety and Health Administration (OSHA) has calculated permissible exposure limits (PEL) for respirable crystalline silica exposure in the workplace averaged over 8-hour shifts. The NIOSH recommended exposure limit (REL) offers an even more protective threshold.

During hydraulic fracturing operations, workers can be exposed to silica dust from multiple sources, including sand movers, transfer belts, mixers, and vehicle traffic. Exposure levels frequently exceed the OSHA calculated PEL and even more so the NIOSH REL in downwind areas or near dust generation points. This alarmingly high exposure puts workers at risk of developing silicosis and other silica-related diseases.

To prevent these hazards, a combination of proper engineering controls, work practices, protective equipment, worker training, and substitution of less hazardous alternative materials whenever feasible is required.

Understanding Hydraulic Fracturing and its Hazards

Hydraulic fracturing uses high-pressure fluid to fracture shale formations to improve access and productivity of oil and gas wells. The fluid is primarily water mixed with proppants and chemical additives.

The proppant—usually sand containing up to 99% crystalline silica—props open the fractures to allow hydrocarbons to flow. Chemical additives serve various functions like friction reducers, corrosion inhibitors, gelling agents and biocides to protect equipment and reservoir integrity.

During fracturing operations, workers may be exposed to respirable silica dust emitted during transportation, handling and mixing of the large volumes of sand. If inhaled, the dust can lead to disabling and sometimes fatal silicosis or lung cancer. Other safety and health hazards also exist at fracking sites related to chemicals, noise, extremity injuries and more.

NIOSH Field Studies on Worker Exposure

Through partnerships with industry, NIOSH collected 116 full-shift air samples at 11 hydraulic fracturing sites across 5 states to assess worker exposure levels to respirable silica dust during common tasks.

Key findings show:

- 47% of samples exceeded the OSHA PEL

- 79% of samples exceeded the NIOSH REL

- In 31% of samples, exposure was 10+ times the NIOSH REL

- Highest exposures occurred near sand movers and mixer operators during dust-generating activities like sand transfer

These exceptionally high exposure levels indicate a need for immediate engineering controls and safe work practices to protect workers, accompanied by proper respiratory protection until exposures can be reduced below RELs.

Adverse Health Effects of Crystalline Silica Exposure

When finely divided silica dust is inhaled, it results in inflammation and scarring of lung tissue leading to several disabling and potentially fatal diseases:

- Silicosis: The most common effect, causing shortness of breath, fatigue and chest pain. Can lead to respiratory failure and death.

- Lung Cancer: Silica exposure strongly linked to increased lung cancer risk.

- COPD: Restrictive airway inflammation and decreased lung function.

- Autoimmune Disorders: Increased risk of rheumatoid arthritis, scleroderma, sarcoidosis.

- Tuberculosis: Accelerated progression with co-exposure.

- Kidney Disease

Symptoms depend on exposure levels and duration and can take years to develop. That’s why ongoing monitoring and early detection are key to prevention.

Recommended Exposure Controls and Work Practices

Under the Occupational Safety and Health (OSH) Act of 1970, employers must provide safe and healthful working conditions. Where silica dust hazards exist, they must implement combinations of engineering and work practice controls, proper respiratory protection, worker training, and less hazardous alternative materials, such as resin-coated proppants, where feasible.

Engineering and work practice controls offer the best protections and should be implemented first, before respiratory protection. Recommended options include:

- Enclosing dust generation sources

- Operating equipment remotely

- Local exhaust ventilation

- Dust collectors on equipment

- Water spray dust suppression

- Reduced or eliminated open transfer points

- Prompt clean-up of spills

- Lower drop heights from belts to mixer hoppers

If engineering and work practice controls cannot sufficiently reduce exposures below OSHA PELs, then employers must provide proper NIOSH-approved respiratory protection and implement a full respiratory protection program in compliance with OSHA Respiratory Protection standard 29 CFR 1910.134.

At a minimum, N95 respirators must be provided. Higher exposures require half or full-face elastomeric respirators or powered air purifying respirators (PAPRs).

In addition to controls, OSHA’s Hazard Communication standard mandates employee training on dust hazards and access to safety data sheets on workplace chemicals like fracking sand. Medical surveillance is also advised for early disease detection.

Cooperative Initiatives Underway

OSHA, NIOSH and industry groups have formed a Respirable Silica Focus Group to further evaluate the problem and find practical solutions to better protect fracking workers. NIOSH also continues field research assessing chemical risks and exploring new dust control technologies applicable to hydraulic fracturing.

These collaborative efforts aim to gather quality exposure data across different regional practices; raise awareness of key health risks; encourage implementation of best-practice engineering controls; and strengthen capabilities through workforce education and training.

Other Safety and Health Hazards

In addition to silica dust, workers are exposed to other serious safety and health hazards at hydraulic fracturing sites which require appropriate protections, including:

- High noise exposure from equipment leading to hearing damage

- Chemical exposures – VOCs, petroleum distillates

- Struck-by and caught-in hazards from hoses/lines/pumps

- Burns from hot surfaces or fluids

- Fall hazards, especially from great heights

- Explosion/fire risk from methane and hydrocarbons

- Overexertion from repeated manual tasks/tools/machinery

- Extreme weather exposure – heat/cold stress

- Fatigue from long shifts/weeks

Proper engineering controls, safe equipment operations, effective work planning, and proper PPE must be utilized to minimize these dangers and prevent needless injuries, ill health effects and deaths.

Conclusion

Worker overexposure to hazardous respirable silica dust during hydraulic fracturing activities remains a serious but often overlooked threat to health and safety. Recent NIOSH and OSHA initiatives aim to better assess these risks across industry sectors and encourage adoption of best-practice protections through guidance, education, cooperative development of improved controls and stronger regulatory enforcement.

By increasing awareness and vigilance and implementing combination prevention strategies to contain, capture and control dust emissions, companies can better protect the wellbeing of their indispensable skilled workforce. Worker safety, health and productivity go hand in hand. There is always more that can be done.

The moral imperative lies with industry leaders to proactively seek lasting upstream solutions that isolate workers from unsafe exposures. This protects both human lives and companies’ bottom lines over the long term. OSHA and NIOSH offer many free educational and consultative services to assist smaller operators as well in providing their essential workers with safe, modern and healthy working conditions.