Alright folks, let’s talk about farm safety, specifically preventing farm vehicle backover incidents. You know, the kind where a big piece of farm equipment accidentally backs into someone. Now, these incidents can be real nasty, but they can be avoided. Employers need to keep their workers safe, and that means making sure they know about these hazards and how to stay out of harm’s way. So, let’s dive into how we can prevent these accidents from happening.

Preventing or Minimizing Backover Hazards

Now, most backover incidents happen because employers aren’t training their operators properly or enforcing good safety practices. To avoid these incidents, we need to make sure operators and workers are always aware of their surroundings and limit unnecessary backing up. And, it’s a good idea to have alternative routes and safety systems in place to help prevent these accidents from happening.

Hitching Farm Equipment and Implements

When it comes to hitching farm equipment, like trucks or tractors, it can be risky for helpers working behind the vehicle. They could end up caught and crushed between the vehicle and the equipment being hitched. That’s why it’s important to have some safety measures in place for hitching operations, whether you’re working alone or with a helper.

Hitching operations without a helper:

- Give your equipment a good once-over, checkin’ out the hydraulic and electrical connections, drawbar hole and hitch pin, and that three-point hitch.

- Make sure there ain’t nobody standin’ or workin’ behind your vehicle.

- If you got one, use that backup camera and alarm to be sure there’s nothing in your way.

- Ease your vehicle back real slow-like, lining up the hole in the drawbar with the hole in the implement hitch.

- Hit the brakes and put ‘er in park, or lock ’em up.

- If needed, hop off to hook up the electrical and hydraulic connections and the safety chains.

- Get that equipment hitched to your vehicle.

- Release the parking brake/lock, shift into gear, and ease on outta there nice and slow.

Hitching operations with a helper:

Got a helper for hitching operations? Follow these steps together.

- Inspect the equipment, including the hydraulic and electrical connections, drawbar hole and hitch pin, and the three-point hitch connection if applicable.

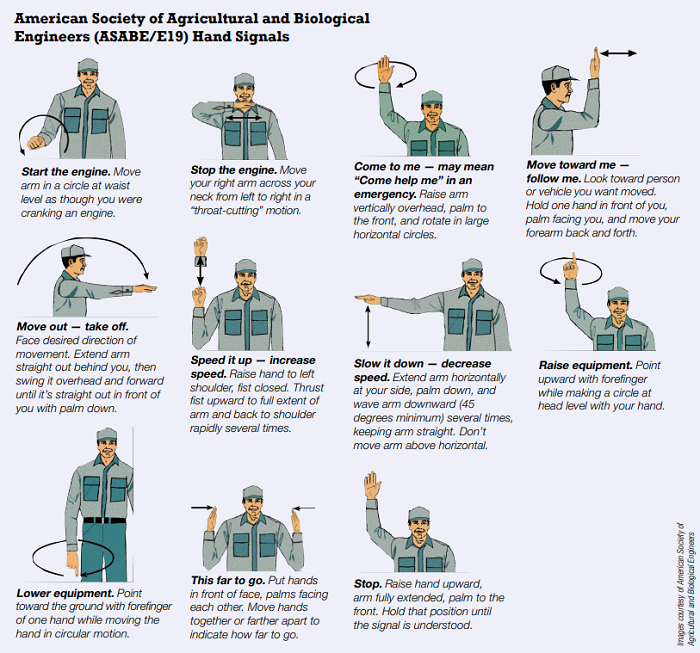

- Make sure you both understand and use coordinated ASABE hand signals (see below for coordinated hand signals).

- Slowly back up the vehicle toward the equipment at the lowest speed possible.

- The helper should stand clear of the vehicle’s path until it comes to a complete stop.

- Once the drawbar and equipment are aligned, stop the vehicle and put it in park, or lock the brakes.

- Signal your helper that it’s safe to approach the vehicle for a close inspection and to get ready for hitching operations.

- If needed, attach the electrical and hydraulic connections and safety chains. Slightly move the vehicle forward or backward, if required, to help your helper drop in the hitch pin.

Prevent backover incidents with these guidelines:

- Regularly assess each work location to determine if a traffic control plan is needed.

- Establish drive-through or circular turnaround areas, or provide adequate space for three-point turns if not possible.

- Ensure all turnaround areas are level, firm, and well-drained to prevent vehicle tipping.

- Determine if a backup camera or system is necessary.

- Prohibit workers from eating or resting near active vehicles and equipment.

- Identify areas where workers might unexpectedly stand or walk.

- Determine if a spotter is required.

- Instruct workers and operators to avoid using personal mobile phones, headphones, or any distracting items.

Working Conditions

Working conditions can play a big role in backover incidents.

Working at night

For example, when working at night, the lack of light can make it hard for operators to see their surroundings. Employers should provide proper lighting for the worksite and require workers to wear reflectors or high-visibility vests to stay visible.

Working in bad weather

Bad weather, like heavy rain, can also cause trouble. It can reduce visibility and make it hard to spot workers or other vehicles. If workers are at risk, employers should stop the work and keep workers clear of moving vehicles until it’s safe.

Training

Training is essential for keeping everyone safe.

Employers should train vehicle operators to:

- Familiarize operators with backing up hazards and worksite safety measures.

- Instruct operators to back up only when necessary and minimize the distance.

- Train operators to check surrounding areas for obstacles, workers, and equipment.

- Ensure operators understand vehicle and equipment limitations and proper operation.

- Emphasize the importance of clean and properly adjusted mirrors to minimize blind spots.

- Teach operators about their vehicle’s blind spots and mirror limitations.

- Ensure backup alarms, sensors, and cameras are functioning properly.

- Instruct operators to check under vehicles and trailers for workers.

- Encourage the use of the vehicle’s horn and 4-way flashers when backing up.

- Advise operators to roll down windows and open doors to hear shouts, if necessary.

- Train operators on the impact of snow, mud, slush, or ice on vehicle control.

- Explain that bad weather can compromise operators’ ability to hear or see warnings.

- Instruct operators to always back up slowly and watch carefully in all directions.

Employers should train farmworkers on foot to:

- Instruct farmworkers to stand where they can see the vehicle’s mirrors when possible.

- Teach farmworkers never to go between a moving vehicle and hitched or towed equipment.

- Advise farmworkers not to stand or linger in a vehicle’s path.

- Train farmworkers to avoid resting or sleeping next to or under work vehicles or equipment.

- Encourage farmworkers to inform others when vehicles are approaching.

- Teach farmworkers to listen for backup alarms and observe vehicle movement.

- Remind farmworkers never to assume the vehicle operator can see them.

- Instruct farmworkers not to wear earbuds or headphones near farm vehicles and equipment.

Using Hand Signals and Spotters

Using hand signals and spotters can improve communication and safety. The American Society of Agricultural and Biological Engineers (ASABE/E19) has developed agricultural hand signals for farm machinery operators. These hand signals can prevent accidents and save time. Employers should train and require drivers and spotters to use the ASABE’s hand signals, especially when noise or distance is a factor.

Vehicle Safety Devices and Warning Systems

Vehicle safety devices and warning systems, like backup alarms, large backup lights, sensors, continuous beeping alarms while in reverse, and rear-view cameras, are essential components of modern farm vehicles. Older agricultural vehicles may lack these safety features. Planning ahead, establishing sound safety procedures, and adding safety warning devices to farm vehicles can help prevent backover incidents and injuries.

Workers’ Rights

Workers have the right to a safe work environment, training in a language they understand, access to records of work-related injuries and illnesses, and the ability to file a complaint with OSHA without retaliation. Employers are responsible for maintaining a safe workplace and complying with OSHA standards.

Conclusion

Backover incidents on the farm can be downright dangerous, but by following these simple tips and tricks, we can keep our hardworking farm families safe and sound. Remember, communication is key—whether it’s hand signals, backup cameras, or just a good honk of the horn. With a bit of planning, training, and the right equipment, we can make sure everyone gets home safely at the end of the day. Stay vigilant, be aware, and let’s keep our farms running smoothly and accident-free. Happy farming, everybody!

For more information on farm safety, visit OSHA’s Agricultural Operations website at https://www.osha.gov/agricultural-operations.

References: