Introduction

Today we’re talking about keeping your digits safe while using some serious kitchen gadgets – food slicers and meat grinders. These bad boys can be found in grocery stores, restaurants, and delis, and let me tell you, they can cause some nasty cuts and even amputations if you’re not careful. So, let’s dive into some tips to keep you and your employees safe.

The loss of a limb is undeniably one of the most devastating workplace injuries, often leading to life-altering disabilities. In 2013 alone, there were more than 4,000 incidents involving meat slicers, which caused workers to miss out on valuable workdays.

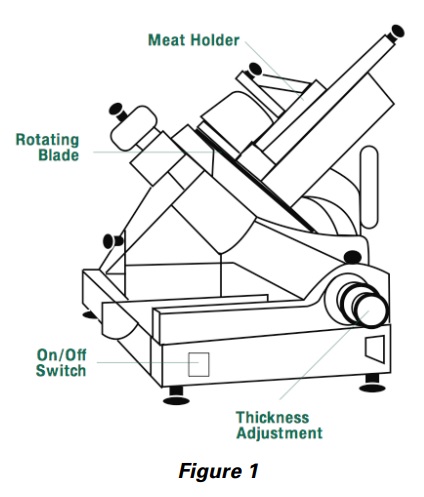

Food slicers (refer to Figure 1) are typically electrically-powered contraptions, outfitted with a spinning blade, an on/off switch, an adjustable thickness setting, and a designated area to hold or guide food. To ensure a proper cut, operators might utilize a push-guard mechanism, a plunger, or even rely on gravity (with or without a special attachment connected to the food holder) to apply pressure against the slicer blade.

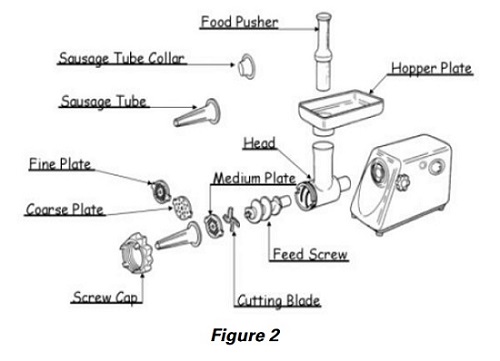

When it comes to electric meat grinders, they’re usually equipped with a feeding tray to hold raw meat as the worker guides it into the machine. The feed screw then takes over, pulling the meat inside the grinder (as shown in Figure 2) and directing it through the cutting plate. Additional components include an on/off switch, a reverse switch, and a food pusher, often referred to as a plunger.

OSHA Regulations

Let’s break down some OSHA regulations you need to be aware of when working with food slicers and meat grinders. Trust me, folks, sticking to these rules will keep everyone in the workplace safe and sound.

Here are the OSHA standards (29 CFR) you need to follow:

- Machine Guarding (1910.212): This standard ensures all moving parts of the machines are properly guarded to protect your workers from any hazards.

- Hand Protection (1910.138): Equip your employees with the right protective gear, like cut-resistant gloves, to keep their hands safe from harm.

- Control of Hazardous Energy (1910.147): Implement a lockout/tagout program to make sure machines are de-energized during maintenance and cleaning.

Keep in mind, if there’s a work-related incident that leads to an amputation – even just a fingertip – you might need to follow 29 CFR 1904.39’s recording and reporting requirements.

And one more important note: The Fair Labor Standards Act (FLSA) says workers under 18 years old can’t operate hazardous powered equipment, like food slicers and meat grinders, in non-agricultural occupations. So, be sure to keep those young workers safe and assign them other tasks.

Preventing Injuries from Food Slicers and Meat Grinders

Operating food slicers and meat grinders can pose serious risks, including severe cuts or even amputations. It’s crucial for employers to ensure workers are equipped with appropriate hand protection, such as cut-resistant gloves, especially when there’s a chance their hands might come into contact with the blades.

Another crucial safety measure is to fully retract the blade (set it to zero) when the slicer isn’t being used or during the cleaning process. Employers should also supply meat grinder operators with properly sized plungers, eliminating the need for workers to place their hands near the feed throat while the machine is in operation.

It’s important to note that operating and cleaning food slicers and meat grinders are two distinct tasks, and each may necessitate additional safety measures to prevent injuries.

Food Slicers

When a food slicer is on or even just energized, the top and bottom parts can be downright dangerous. Workers’ hands and fingers might come in contact with the blade, and that’s a recipe for some serious injuries.

Make sure you’re using rotary blade food slicers with guards that cover the unused parts of the blade on both top and bottom. Get slicers that already come with a feeding attachment on the sliding mechanism, or buy the attachment separately and install it before use.

Now, let’s go over some essential worker training topics:

- Never put a hand behind the food chute guard.

- Don’t place food into the slicer by hand-feeding or applying hand pressure.

- Use a pushing/guarding device with chute-fed slicers.

- Employ plungers to feed food into chute-fed slicers, or use the feeding attachment on the food holder.

- Switch off the food slicer when changing foods.

- Keep hands clear of the danger zone at the back of the blade where sliced food exits.

- Turn off and unplug slicers when they’re not in use or left unattended, even for a short time.

Keep these safety tips in mind, and you’ll be slicing like a pro while keeping those fingers intact.

Meat Grinders

Employers bear the responsibility of ensuring that meat grinders are fitted with a primary safeguard, such as a well-designed tapered throat or fixed guard, to protect workers from potential contact with the point-of-operation (specifically, the auger cutter area).

Key topics to include in worker training sessions are:

- Always use an appropriate plunger for feeding meat into the grinders.

- Only operate grinders when feeding trays and throats are properly installed.

- Utilize the meat grinder exclusively for its intended purpose.

- When not in use, or left unattended for any duration, make sure to turn off and unplug the grinder.

Preventing Injuries When Maintaining/Cleaning a Food Slicer or Meat Grinder

Now, when you’re maintaining or cleaning these gadgets, you’ll need to remove protective guards. Employers should make sure the slicer or grinder doesn’t suddenly start up and that workers’ hands are protected from nasty cuts or amputations.

A Lockout/Tagout (LO/TO) program, as required by 29 CFR 1910.147, is essential when guards are removed. However, if the worker unplugs the slicer from the energy source and has exclusive control of the plug, a LO/TO program isn’t necessary.

A solid LO/TO program should include:

- Procedures for locking out or tagging out food slicers.

- Specific LO/TO training.

- Periodic review of LO/TO procedures to make sure all requirements are met.

For safe maintenance and cleaning practices, follow the manufacturer’s operating manual, which typically includes:

- Using a cleaning device with a handle to add distance between your hand and sharp edges.

- Wiping the blade from the center outward to avoid contact with the blade edge.

- Never wiping toward the blade when cleaning the slicer table.

Essential Training Employers Must Provide

Employers need to ensure all operators receive hands-on training, guided by experienced professionals, until they can safely perform their tasks independently. Comprehensive operator training should be based on the manufacturer’s recommendations, encompassing equipment-specific topics that cover the following safe operating and cleaning procedures for the equipment being used:

- Recognizing hazards associated with food slicers and meat grinders

- Understanding the proper use of required safeguards and their protective function

- Knowing when and how to remove safeguards (typically, only by repair or maintenance personnel)

- Preventing accidental start-ups during cleaning or maintenance with the correct LO/TO procedures

- Knowing when to use hand protectors and understanding their limitations

- Identifying the appropriate steps (e.g., notifying the supervisor) if a safeguard is damaged, missing, or fails to provide adequate protection

Training is vital for new operators, maintenance or setup staff, when introducing new or modified safeguards, or when assigning workers to a different machine or operation.

Helpful Resources

Youth Worker Safety in Restaurants eTool – Food Preparation, OSHA:

http://www.osha.gov/SLTC/youth/restaurant/equipment_foodprep.html

Safeguarding Equipment and Protecting Employees from Amputations, OSHA publication 3170-02R, 2007:

http://www.osha.gov/Publications/OSHA3170/3170-02R-2007-English.html

Meat Slicer Training and Safety, University of California Riverside:

https://ehs.ucr.edu/document/safetydiningmeat-slicer-safety

Many manufacturers have also developed and posted videos on food slicer and meat grinder general use, cleaning, and safety.

References: