Trenching and shoring are common activities in construction environments, but they also pose significant safety risks if not done properly. In this article, we’ll provide some helpful advice to businesses on how to ensure safe and effective trenching and shoring in construction environments.

First and foremost, it’s important to ensure that all employees receive proper safety training. This includes training on how to properly excavate trenches, install shoring systems, and use personal protective equipment (PPE) appropriately. It’s also a good idea to conduct regular safety meetings and drills to reinforce safety protocols and procedures.

One of the most effective ways to prevent accidents and injuries related to trenching and shoring is by following proper excavation procedures. This includes conducting a thorough site assessment before beginning work, determining the location of underground utilities, and marking the area.

It’s also essential to use appropriate shoring systems to support the sides of the trench and prevent cave-ins. Ensure all shoring systems are properly installed and maintained and follow all manufacturer instructions and guidelines.

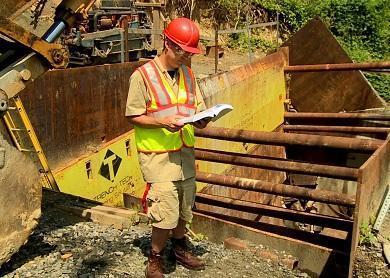

In addition, it’s important to use appropriate PPE when working in trenches. This may include hard hats, protective eyewear, earplugs, and other protective gear.

It’s also essential to follow proper load-bearing guidelines when working in trenches. Never exceed the recommended load capacity for the shoring systems, and make sure that all materials and equipment are securely placed within the trench.

Here are ten tips to help businesses ensure safe and effective trenching and shoring in construction environments:

- Provide proper safety training to all employees: This includes training on how to properly excavate trenches, install shoring systems, and use personal protective equipment (PPE) appropriately.

- Follow proper excavation procedures: Conduct a thorough site assessment before beginning work, determine the location of underground utilities, and mark the area.

- Use appropriate shoring systems: Ensure all systems are properly installed and maintained and follow all manufacturer instructions and guidelines.

- Wear appropriate PPE: Use hard hats, protective eyewear, earplugs, and other protective gear when working in trenches.

- Follow load-bearing guidelines: Never exceed the recommended load capacity for the shoring systems, and make sure that all materials and equipment are securely placed within the trench.

- Maintain a clean and organized worksite: Keep the area around the trench free of clutter and obstructions to reduce the risk of accidents and injuries.

- Use caution when working near underground utilities: Be aware of the location of underground utilities and take appropriate precautions to avoid accidents and injuries.

- Use proper lifting techniques: Follow safe lifting practices when moving materials or equipment into or out of trenches.

- Secure loose materials and equipment: Ensure all materials and equipment are securely placed within the trench to prevent them from falling or shifting.

- Inspect shoring systems regularly: Conduct regular inspections of them to ensure that they are in good working condition and free of defects.

In conclusion, trenching and shoring are essential activities in construction environments, but they also pose significant safety risks. By providing proper safety training, following proper excavation procedures, using appropriate shoring systems, wearing appropriate PPE, following load-bearing guidelines, and maintaining a clean and organized worksite, businesses can ensure safe and effective trenching and shoring and create a safer work environment for their employees.

Do you need Online Construction Safety Training?

Try a free demonstration of Trenching and Shoring in Construction Environments