This article aims to raise awareness about the potential dangers associated with unloading stone slabs from containers, storing them in “slab-racking” systems, maneuvering and handling stone slabs with equipment, and loading stone slabs onto trucks. While this article is not a standard or regulation and does not impose new legal obligations, it offers advisory, informational content to help employers maintain a secure and healthy work environment.

The purpose of this article is to:

- Notify employers and employees about the risks linked to slab handling, transport, storage, loading, and unloading operations.

- Offer information and suggestions to reduce the possibility of employee injuries during these operations.

- Encourage employers to establish stone slab handling procedures in their workplaces.

- Emphasize the importance of training employees on safe workplace procedures.

- Ensure that employees adhere to safe stone slab handling procedures.

Severe injuries and fatalities can happen during the handling, loading, and unloading of large, heavy stone slabs, which can range in weight from a few hundred to several thousand pounds. In 2005, OSHA issued a Safety and Health Information Bulletin (SHIB) outlining the hazards related to transporting and unloading stone slabs from delivery trucks. However, that SHIB didn’t cover the risks associated with unloading stone slabs from containers or other unique in-house handling hazards that could lead to severe injuries and fatalities. This article seeks to address those gaps and provide a comprehensive understanding of the safety measures required.

Unloading Stone Slabs from Containers

Some suppliers use wooden supports to keep slab bundles steady during transport. Without these supports, slabs may shift or collapse. Employees have been trapped or crushed when removing supports due to unexpected slab movement.

Storing Stone Slabs

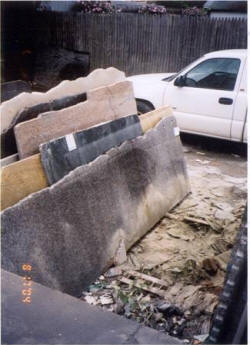

After off-loading, slabs often go on racks. These can be metal or wood, like the A-frame type. Slabs lean against the A-frame or another slab.

Sometimes, A-frames don’t hold the slab weight or prevent movement when removing a slab. Slabs may not be secured or inspected for stability.

When positioning slabs vertically, employees may stand in the “fall shadow,” risking crushing injuries or death if the slab tilts too much.

“Slab racks” store slabs with horizontal bases and poles. They’re similar in design, with holes in bases for pole insertion. Slabs sit between poles, handled by equipment.

Rack system failure is common. Overloaded racks deform bases, dislodging poles from the bottom hole, causing instability and rack failure.

Objects or debris in base holes can cause instability by preventing full pole insertion.

Handling and Moving Stone Slabs

Machinery like cranes and powered industrial trucks transport slabs within facilities. Rigging devices aid in lifting.

Before moving slabs, employees risk being crushed while attaching clamps or lifting devices. Improper wedge use or positioning between slabs can lead to accidents.

Loading Stone Slabs onto Flatbed Trucks

Slabs are loaded onto flatbed trucks using machinery like powered industrial trucks with booms or overhead cranes. Trucks have A-frame supports or pole racking systems to hold slabs during transport. Loading employees face caught-by, struck-by, and/or crushed-by hazards.

General Recommendations

Employers handling and storing slabs must prevent caught-by, struck-by, and/or crushed-by hazards. Here are some general recommendations:

- Pre-plan work to identify hazards, safe practices, and necessary equipment.

- Develop and implement safe procedures for transporting, loading, and unloading slabs.

- Provide suitable mechanical handling equipment.

- Inspect equipment before use, ensuring it’s in good condition. Repair or replace defective equipment.

- Train employees in proper material handling procedures.

- Make sure employees follow safe slab handling procedures.

Recommendations for Stone Slab Storage

To minimize hazards with “stone racks” and other storage racks for slabs, follow these recommendations:

- Design storage racks to withstand loads and forces.

- Create a rack system that secures slabs from shifting, sliding, and collapsing, or provide secondary bracing or a restraint system.

- Ensure “slab racks” are properly installed, inspecting components to guarantee pole insertion.

- Keep racks clear of debris or objects interfering with pole insertion in “slab racks.”

- Implement procedures for placing and removing slabs from racks while keeping employees safe.

- Don’t let employees use damaged storage racks.

- Inspect storage racks before loading, checking for:

- Cracked welds

- Cracked structural members

- Deformed or bent structural members

- Splits in wooden supports

- Signs of damage or overloading

- Poles or uprights not seated correctly in sockets or holes.

Suggestions for Handling and In-house Transportation of Stone Slabs

To minimize potential hazards related to handling and transporting stone slabs, consider the following recommendations:

- Opt for mechanical aids (e.g., slab dollies, suction lifts, scissor clamps) instead of manual lifting whenever possible. Only lift loads that can be safely handled.

- Utilize appropriate material handling equipment, such as:

- Overhead cranes with approved attachments

- Forklift trucks with approved boom attachments and lifting devices

- Other suitable equipment to assist with unloading and loading slabs

- When moving or lifting a slab with a scissor clamp, place the clamp on the secure area of the stone. Using clamps on grade “A” marble and other solid stones without flaws, open seams, or cracks is ideal.

- Ensure that suction cup lifters are rated for lifting unpolished slabs.

- Avoid using scissor clamps on equipment operating on uneven surfaces.

- When moving a slab with an overhead crane, never stand under, near, or in the fall shadow of a slab. Utilize a tag line to control suspended slabs and prevent them from falling or toppling.

- Always walk at the end of the slab and avoid the “fall shadow” area where a slab could land and topple if it were to fall.

- Confirm that dollies used for moving stone slabs can support the slab’s weight, and have employees walk on either end of the dolly for support.

- When using powered industrial trucks, raise the load only as high as necessary to clear obstacles or the road surface.

- Handle loads within the rated capacity of the truck when using powered industrial trucks.

- Remove supports and bracing from stone slab bundles inside shipping/storage containers in a sequence that prevents other slabs from shifting or collapsing.

References:

- 29 CFR 1910.176, Handling materials-general, Occupational Safety and Health Administration

- 29 CFR 1910.178, Powered Industrial Trucks, Occupational Safety and Health Administration

- 29 CFR 1910.179, Overhead and Gantry Cranes, Occupational Safety and Health Administration

- https://www.osha.gov/publications/shib081208