Introduction

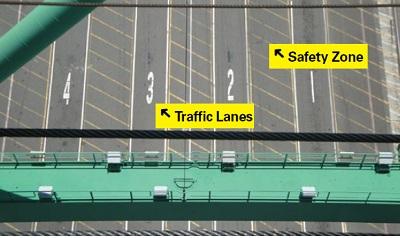

The handling of cargo in marine terminals is essential for global trade, but it poses significant safety risks to the workers involved. Workers risk being struck by the various moving vehicles and heavy machinery operating in busy port environments. To mitigate these risks, the Occupational Safety and Health Administration (OSHA) advises employers to clearly demarcate traffic lanes for vehicles and personnel safety zones for workers on foot.

Properly established traffic lanes and safety zones are crucial for preventing injuries and fatalities among longshore workers and others involved in marine cargo operations. This article will explore OSHA guidance on designing these zones to optimize safety. We will cover key considerations like lane widths, zone sizes, special cargo accommodations, traffic patterns under cranes, and more. Following these best practices can dramatically improve visibility, communication, and coordination between vehicle drivers and vulnerable workers on foot in congested terminals.

Traffic Lane Design and Vehicle Considerations

OSHA recommends marking wide traffic lanes dedicated for vehicles and equipment like bomb carts, straddle carriers, haulage equipment, and semi-tractors involved in cargo loads. These lanes should be clearly distinguishable from personnel safety zones for workers. Consider the following when designing traffic lanes:

• Make traffic lanes wide enough to fit the largest expected vehicle type to prevent overflow into adjacent zones. For example, consider maximum widths and turning radii.

• Guide drivers so vehicles and equipment stay aligned within the traffic lane under the crane to prevent protrusion. For straddle carriers, this means properly centering the lane between the legs.

• Semi-tractors should travel within marked lanes to keep the haulage equipment contained inside the lane boundaries.

• Consider needing occasional extra clearance for oversized specialty cargo on flatbeds, low boys, mafis, etc. that may extend further.

• Establish clear, consistent traffic flow patterns under the crane so vehicle movements become habitual for operators and workers can anticipate directions at all times. Any deviations should be clearly communicated.

Personnel Safety Zone Configuration

In addition to vehicle traffic lanes, provide clearly marked personnel safety zones to either side where workers on foot can operate protected from potential traffic hazards. Follow these OSHA guidelines for establishing appropriately sized safety zones:

• Make personnel zones wide enough to fully contain common foot traffic worker tasks. This means ensuring adequate space for workers to walk freely around work stations like cone boxes without encroaching into adjacent lanes.

• Position cone boxes fully inside the personnel zone and offset from the boundary with traffic lanes. Provide enough periphery clearance so workers don’t have to step into lanes to access boxes.

• During specialized operations like using bomb carts under the crane, relocate obstructions like cone boxes out of the crane’s area of activity above to keep zones clear for workers.

• Do not allow vehicle components like hatch covers to extend into marked personnel zone boundaries during cargo loads and unloads.

• Consider further special provisions to maintain buffer zones around workers setting up or handling oversized cargo in transit near traffic lanes.

• Coordinate traffic and pedestrian flows under the crane carefully during any unusual or exceptional scenarios requiring temporary lane deviations. Ensure workers are clearly informed of any changes.

Implications for Worker Safety

When marine terminal traffic lanes and personnel safety zones are designed holistically using OSHA guidance, the stage is set for dramatically safer cargo operations. Workers on foot are protected from all sides against traffic hazards they frequently face in their hazardous occupation. Clearly delineated vehicle lanes guide drivers and heavy equipment operators to maintain safe buffer zones from vulnerable longshoremen, coners, signalers, and others working at ground level.

Well-defined zones allow for optimized traffic flow under cranes and through the congested spaces of marine terminals. They provide all parties better situational awareness and visibility of each other’s presence and movements. This further facilitates hand signaling, equipment spotting, and other communication critical for coordination. Such proactive environmental design leverages human perception, habit, communication and caution against risk factors that have historically injured or killed in this industry segment.

Following best practices for traffic and safety zones also leads to better rule compliance across hierarchical terminal organizations. From upper management establishing policies, to yard supervisors overseeing operations, to everyday dockworkers and vehicle operators working together safely – everyone understands the protocols set in place to protect those alongside heavy freight flows in dense settings.

Conclusion

Creating more forgiving conditions through work zone environmental design helps prevent adverse worker-vehicle interactions in marine cargo handling. It represents an ethical proactive approach to organizational safety culture. Workers rightfully expect management to implement every reasonable measure available before placing them in harm’s way. Integrating OSHA guidance to provide clearly delineated traffic lanes and personnel safety zones around vulnerable activities meets that responsibility. While no single solution can eliminate all risks on busy docks, this intervention targets one of the most severe and likely hazards these workers face. Prioritizing this long-recommended safety upgrade pays dividends through boosted efficiency and morale as well as reduced injuries. By following these best practices, marine terminal operators can significantly improve their safety outcomes and regulatory compliance while optimizing cargo movement. The result is a model of safety and collaboration between workers and management, where the sanctity of human life is respected alongside operational objectives.