Introduction

Exposure to hexavalent chromium (Cr(VI)) poses significant health hazards to workers, including lung cancer, irritation or damage to the respiratory system, and burns on the skin and eyes. Recognizing these serious risks, the Occupational Safety and Health Administration (OSHA) has established legally enforceable permissible exposure limits (PELs) and other protections for workers exposed to this toxic compound.

OSHA’s Hexavalent Chromium

Standards outline requirements to limit Cr(VI) exposures, monitor worker exposures, implement exposure control measures, provide personal protective equipment, establish proper workplace hygiene practices, conduct medical surveillance, and train workers. Adhering to these critical safeguards can truly save lives by preventing occupational illnesses and deaths from Cr(VI). This article will explore OSHA’s Hexavalent Chromium rule in detail, unpacking key definitions, exposure monitoring protocols, exposure control methods, medical surveillance provisions, and other vital facets of the standards.

Worker Exposure and Health Consequences

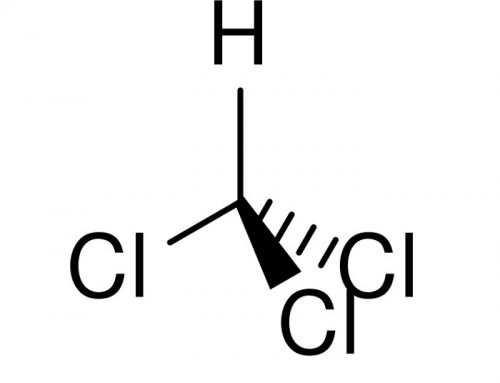

Hexavalent chromium (chromium(VI), Cr(VI), chromium 6) is chromium in any chemical compound that contains the element in the +6 oxidation state (thus hexavalent). Hexavalent chromium compounds are rarely found naturally, but frequently used in industrial processes involving pigments, metal finishing, tanning, oxidizing agents, and more. Subsequently, many American workers face Cr(VI) exposures during production activities or while performing welding or other hot work on chrome-containing metals. When inhaled or contacting skin, Cr(VI) compounds can inflict acute local injury as well as longer-term systemic health effects.

Specifically, Cr(VI) is a confirmed human carcinogen associated with elevated lung cancer mortality. Exposure has also been linked to asthma, dermatitis, nasal septum perforations, and other respiratory, skin, and eye damage. OSHA’s permissible exposure limits, exposure monitoring, engineering and administrative controls, protective equipment requirements, medical surveillance, and training mandates all aim to prevent these serious and life-threatening chromium health effects.

OSHA’s Hexavalent Chromium Exposure Limits

OSHA’s general industry, shipyard, and construction hexavalent chromium standards establish an 8-hour time-weighted average (TWA) permissible exposure limit (PEL) of 5 micrograms per cubic meter (μg/m3) of air. This PEL, reflecting the maximum allowed average Cr(VI) exposure over an 8-hour shift, triggers key provisions for exposure monitoring, controls, and medical surveillance.

In addition, the standards set an Action Level of 2.5 μg/m3 as an 8-hour TWA exposure. This lower threshold activates additional requirements including exposure determination, periodic monitoring, and training. Any Cr(VI) exposure above the 5 μg/m3 PEL signifies unacceptable working conditions requiring more stringent controls and safeguards per the standard.

Exposure Monitoring and Determinations

To fully protect personnel from Cr(VI)’s insidious health effects, employers must accurately characterize exposures through initial and ongoing monitoring. This entails assessing work area Cr(VI) concentrations through either the “scheduled monitoring option” with prescribed testing frequencies or a more flexible “performance-oriented option.”

Under scheduled monitoring, the employer performs initial personal exposure monitoring for each shift and job classification to determine 8-hour TWA exposures. Periodic monitoring then continues every 3, 6, or 12 months depending on whether exposures exceed the PEL, fall between the Action Level and PEL, or remain below the Action Level. Through rigorous monitoring as stipulated in the standards, dangerous chromium overexposures come to light before workers’ health suffers.

Exposure Control Measures

Whenever monitoring indicates hexavalent chromium exposures above the PEL, OSHA requires engineering and work practice controls to reduce and maintain levels at or below 5 μg/m3. This hierarchy of controls approach first applies substitution or isolation methods before turning to ventilation or other solutions. For example, an employer may replace high-chromium alloys used during welding processes with safer materials containing little or no chrome. This elimination method constitutes the most reliable engineering control.

If engineering controls still don’t reduce exposures sufficiently, then administrative adjustments or personal protective equipment must also be implemented per OSHA requirements. Strict adherence to the standards’ provisions on exposure controls prevents avoidable illness, disability, and death among American’s Cr(VI)-exposed workers.

Requirements for Protective Work Clothing and Equipment

In workplaces with potential skin or eye exposures to chromium, OSHA mandates that employers select and provide appropriate protective garments, such as gloves, aprons, suits, hoods, or goggles. These items safeguard the eyes and skin from corrosive or toxic contact.

But protective gear only works when used correctly, so the standards also cover handling contaminated clothing, ensuring workers remove PPE before breaks, isolating soiled items, and properly cleaning or discarding tainted garments. Taken together, these comprehensive provisions on protective clothing and equipment prevent countless skin ulcerations, serious burns, and other chromium contact illnesses.

Hygiene Areas and Practices

Given hexavalent chromium’s hazards, OSHA’s general industry standard strictly governs workplace cleaning and contamination control through housekeeping and hygiene regulations. These include:

- Requiring readily accessible washing facilities capable of removing chromium from skin

- Mandating separation of street clothes from chromium-tainted work clothing via provision of clean change rooms

- Ensuring eating and drinking areas remain as chromium-free as possible

- Stipulating appropriate procedures for handling, storing, and cleaning protective garments and equipment

While not technically feasible for all construction sites and shipyards, adherence to hygiene and housekeeping best practices in these settings still proves critical for health protection. Overall, contamination prevention through proper hygiene and cleaning methods prevents additional exposures that could cause skin ulcerations, burns, nasal damage, or even cancer.

Medical Surveillance Provisions

Considering Cr(VI)’s severe health consequences, medical surveillance allows early detection of adverse changes from exposure. Per OSHA requirements, a physician or other licensed health care professional (PLHCP) must perform medical examinations on workers exposed above the Action Level for 30+ days annually. These plant medical directors or occupational health nurses coordinate testing such as lung functioning tests, skin checks, and supplementary cancer screening.

The PLHCP then determines if any identified conditions might increase risk of impairment from ongoing exposure. For instance, asthma onset or dermatitis in a worker might warrant proposed restrictions on future chromium exposures. Overall, meticulous medical monitoring and vigilant physician review safeguards those working with chromium from further harm.

Training and Communication Requirements

For any safety program to succeed, the involved workers must grasp key hazards and protections. To this end, OSHA mandates training to ensure comprehension of the provisions of the Hexavalent Chromium standards and the associated medical surveillance program. Hazard communication per existing law also applies, so that facilities using chromium provide access to Safety Data Sheets and label containers appropriately.

Through multidimensional education efforts, personnel learn to recognize chromium compounds, understand associated health risks, implement proper procedures for safe use/handling, correctly employ PPE and hygiene practices, and know how to act in emergency situations.

Recordkeeping Responsibilities

In enforcing its health standards, OSHA reviews employers’ data trails, including exposure records, medical testing results, and objective exposure determinations. Therefore, the agency’s Chromium(VI) rule details exact recordkeeping requirements on air monitoring outputs, medical opinions, worker training logs, and more. Maintained for 30+ years, these indispensable documents connect today’s work with future health outcomes.

If current or prior employees later develop cancer, checking historical plant records assists physicians in identifying causal exposures. Thus, fastidious Cr(VI)-related recordkeeping provides the keystone supporting medical surveillance, hazard awareness, and enforcement efforts for generations to come.

Conclusion

In summation, hexavalent chromium remains an insidious occupational hazard accountable for tens of thousands of American worker deaths over past decades. Yet OSHA’s comprehensive standards now regulate chromium use through monitoring, rigorous controls, medical oversight, communication, and transparency. Conscientious employers adhering to these provisions demonstrate their priority for human health over profits.

Workers also play a key role by remaining ever vigilant to avoid exposures. Through collaborative prevention efforts empowered by OSHA’s rule, we stride closer to eliminating this persistent chemical hazard from our nation’s workplaces. The provisions outlined here – if fully implemented – possess great potential to save lives moving forward.