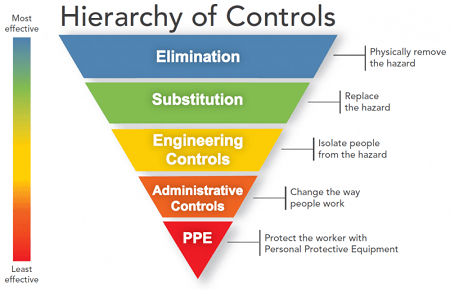

Understanding the Hierarchy of Controls and Why It’s Important

When it comes to controlling hazards in the workplace, the Hierarchy of Controls is a widely accepted framework for identifying and implementing effective controls. The hierarchy of controls is a systematic approach to reducing or eliminating hazards by starting with the most effective controls and working down the list to the least effective. This framework is particularly important during a pandemic, such as COVID-19, where controlling the spread of the virus is of the utmost importance.

In a pandemic like COVID-19, it’s important to apply the hierarchy of controls to reduce the risk of infection and spread of the virus. By identifying and implementing the most effective controls, organizations can protect the health and safety of employees, customers, and the community. Additionally, it’s important to remember that the hierarchy of controls is not a one-size-fits-all approach, and that different controls will be more effective in different situations.

The Hierarchy of Controls framework is particularly important during a pandemic such as COVID-19, where controlling the spread of the virus is of the utmost importance. As the article delves deeper, it highlights the importance of starting with the most effective controls first and utilizing them to reduce or eliminate hazards. By identifying and implementing the most effective controls, organizations can protect the health and safety of employees, customers, and the community. Additionally, it’s important to remember that the hierarchy of controls is not a one-size-fits-all approach, and that different controls will be more effective in different situations. The rest of the article will further explore the specific measures and actions that organizations can take to apply the hierarchy of controls in a pandemic such as COVID-19.

Use the Most Effective Controls First

When applying the hierarchy of controls in a pandemic, it’s important to start with the most effective controls first. The most effective controls are those that eliminate hazards altogether, such as eliminating a hazardous process or material. For example, in the case of COVID-19, the most effective control is to eliminate exposure to the virus altogether by implementing remote work or telecommuting for employees. This can be a more effective control than providing personal protective equipment or implementing engineering controls to reduce exposure.

Eliminating hazards altogether is not always possible, and organizations may need to consider other options such as substituting less hazardous materials or processes, implementing engineering controls, or providing personal protective equipment. However, it’s important to remember that the most effective controls should always be the first line of defense. By starting with the most effective controls, organizations can reduce the risk of infection and spread of the virus in the most efficient and effective way possible.

It is also important to remember that the most effective controls are those that are based on the specific hazards and risks that are present in the workplace. This means that organizations should conduct a thorough assessment of the risks of the specific hazards that are present, and should apply the most effective controls accordingly. This can include identifying the specific areas of the workplace where the virus is most likely to spread, and taking steps to eliminate or reduce exposure in those areas. By focusing on the most effective controls first, organizations can make the most of their resources and efforts to reduce the risk of infection and spread of the virus.

Eliminate Hazards Where Possible

Eliminating hazards altogether is the most effective control, and it’s important to consider this option whenever possible. In a pandemic like COVID-19, this can include eliminating exposure to the virus altogether by implementing remote work or telecommuting for employees. This can be a more effective control than providing personal protective equipment or implementing engineering controls to reduce exposure. For example, in an office setting, instead of implementing engineering controls such as installing barriers between workstations, an organization could choose to have employees work remotely, which is eliminating the hazard altogether.

Another example of eliminating hazards where possible is when it comes to certain tasks or processes in the workplace. Instead of implementing engineering controls or providing personal protective equipment, organizations can consider substituting a less hazardous material or process. For instance, in a manufacturing facility, instead of using a chemical that poses a respiratory hazard, they can consider using a safer alternative material. In this way, organizations can eliminate the hazard altogether and create a safer work environment for all employees.

It’s important to note that eliminating hazards altogether isn’t always possible, and organizations may need to consider other options such as substituting less hazardous materials or processes, implementing engineering controls, or providing personal protective equipment. However, it’s important to keep in mind that eliminating hazards is the most effective control and should be the first line of defense. By eliminating hazards where possible, organizations can take a proactive approach to reducing the risk of infection and spread of the virus, and create a safer work environment for all employees.

Substituting Less Hazardous Materials or Processes

Substituting less hazardous materials or processes is another way to control hazards in the workplace. This involves replacing a hazardous material or process with a less hazardous alternative. For example, in a manufacturing facility, instead of using a chemical that poses a respiratory hazard, an organization could choose to use a safer alternative material. This can be a more effective control than implementing engineering controls or providing personal protective equipment.

In the context of a pandemic, substituting less hazardous materials or processes can be applied in multiple ways. For example, instead of having in-person meetings, organizations can substitute it with virtual meetings to reduce the risk of infection and spread of the virus. Another example is instead of using an in-person training program, an organization can use an online training program. This way, organizations can continue to provide essential training for their employees, while reducing the risk of infection and spread of the virus.

It’s important to note that substituting less hazardous materials or processes is not always possible, and organizations may need to consider other options such as implementing engineering controls, providing personal protective equipment or eliminating hazards altogether. However, by substituting less hazardous materials or processes, organizations can take a proactive approach to reducing the risk of infection and spread of the virus, and create a safer work environment for all employees.

Engineer Controls to Reduce Exposure

Engineering controls are designed to physically change the work environment or process to reduce or eliminate exposure to hazards. In a pandemic like COVID-19, engineering controls can include installing barriers between workstations, increasing ventilation, or installing air filtration systems. These controls can be effective in reducing the risk of infection and spread of the virus, but they are not always the most effective control.

For example, in an office setting, installing barriers between workstations can help reduce exposure to the virus, but it may not be as effective as remote work or telecommuting. In a retail store, installing barriers at cash registers, using plexiglass shields, and implementing one-way traffic can help reduce exposure to the virus. In a manufacturing facility, implementing engineering controls such as installing ventilation systems, and providing protective equipment for employees can help reduce exposure to the virus.

It’s important to note that engineering controls are not always the most effective control, and organizations may need to consider other options such as substituting less hazardous materials or processes, eliminating hazards altogether, or providing personal protective equipment. However, by implementing engineering controls, organizations can take a proactive approach to reducing the risk of infection and spread of the virus, and create a safer work environment for all employees.

The Importance of Personal Protective Equipment (PPE)

Providing personal protective equipment (PPE) is an important step in the hierarchy of controls when it comes to controlling hazards in the workplace, especially during a pandemic. Personal protective equipment such as masks, gloves, face shields, and gowns can help to reduce the risk of infection and spread of the virus by protecting workers from exposure to the virus. PPE can also help to reduce the risk of infection for workers who are in close contact with people who have or may have COVID-19. It is important to note that PPE should be used in conjunction with other controls, such as engineering controls and administrative controls, to effectively reduce the risk of infection.

It is important to ensure that employees have the appropriate PPE for the task they are performing and that they are trained on how to properly use, maintain and dispose of the PPE. Regularly check the condition of the PPE and replace as needed. Also, it is important to ensure that the PPE is stored properly and is readily available for employees to use when needed. It is important to keep in mind that PPE can be used as a last line of defense, but it is not a substitute for other controls. By effectively providing and using personal protective equipment, organizations can help to protect the health and safety of employees and the community during a pandemic.

The Importance of Monitoring and Evaluating Controls

Monitoring and evaluating controls is a crucial step in the hierarchy of controls when it comes to controlling hazards in the workplace, especially during a pandemic. Regularly monitoring and evaluating controls helps to ensure that they remain effective and relevant. This includes assessing the effectiveness of the controls in reducing the risk of infection and spread of the virus, and identifying any areas for improvement. By monitoring and evaluating controls, organizations can make adjustments as necessary to ensure that the controls remain effective and that the risk of infection and spread of the virus is being minimized.

One way to monitor and evaluate controls is to keep track of the number of COVID-19 cases among employees. This can help to identify if a certain control is not effective or if there are any specific areas of the workplace where the risk of infection is higher. Additionally, it is important to conduct regular inspections of the workplace to ensure that controls are being implemented correctly, and that employees are following the necessary procedures. This includes checking that social distancing measures are being followed, that PPE is being used correctly, and that the workplace is being cleaned and disinfected regularly. By effectively monitoring and evaluating controls, organizations can help to protect the health and safety of employees and the community during a pandemic.

The Importance of Combining Different Controls

Implementing a combination of controls is crucial for effectively controlling the spread of a virus in the workplace during a pandemic. The Hierarchy of Controls framework suggests using the most effective controls first and working down the list to the least effective. However, it’s important to remember that different controls will be more effective in different situations, and a combination of controls may be necessary to effectively control the spread of the virus.

For example, eliminating hazards where possible, such as by closing offices or switching to remote work, is one of the most effective controls. But this may not be possible in all situations, such as in manufacturing or healthcare settings. In these cases, engineering controls, such as installing physical barriers or ventilation systems, and administrative controls, such as implementing social distancing and mask-wearing policies, can be used to reduce exposure. Personal protective equipment, such as masks or gloves, can also be used as a last resort. By combining these different controls, organizations can create a safer work environment for all.

Conclusion – The Power of The Hierarchy of Controls in a Pandemic

Applying the hierarchy of controls in a pandemic is a powerful tool for reducing the risk of infection and spread of the virus. By identifying and implementing the most effective controls, organizations can protect the health and safety of employees, customers, and the community. Additionally, it’s important to remember that the hierarchy of controls is not a one-size-fits-all approach, and that different controls will be more effective in different situations. By implementing a combination of controls, organizations can effectively control the spread of the virus and create a safer work environment for all. The Hierarchy of controls is a valuable tool for controlling hazards in the workplace, especially during a pandemic.