Aerial lifts come in handy in shipyards and boatyards when it’s just not practical to set up staging. But let’s face it, these boom-supported platforms and cherry pickers can be downright dangerous if not used properly. We’re talking boom failure, tip-overs, falls, and ejections – none of which sound like a good time.

Employers need to step up to the plate and make sure their workers have a safe environment, which means providing well-maintained equipment, proper supervision and training, fall protection, and a plan for speedy rescue if someone takes a tumble.

Now, for some safe work practices:

- Always, always, always tie off.

- Strap on a body harness and attach the lanyard to a solid anchorage point.

- Don’t go moving the lift when workers are up in the air.

- Train those operators to use the equipment safely and correctly.

- Follow the manufacturer’s instructions when it comes to maintaining and operating the equipment.

- Make sure the equipment controls are clearly marked.

- Don’t even think about overriding safety devices – that’s just asking for trouble.

- If the lift’s on a barge, pay attention to the list, trim, and lash-down points.

- Put stops in place to avoid driving off when the lift is near open edges and can move.

- Be mindful of the swing radius so you don’t accidentally smack into nearby structures.

- Don’t get between structures and the lift when elevated – nobody wants to be crushed.

- To prevent tip-overs, set the brakes, use wheel chocks, check tire pressure, extend outriggers, and make sure the lift is level. Oh, and don’t operate in high winds or under power lines.

A few important reminders:

- A Personal Flotation Device (PFD) isn’t going to help much if a worker falls from heights over 40 feet into the water or onto objects below. Always tie off.

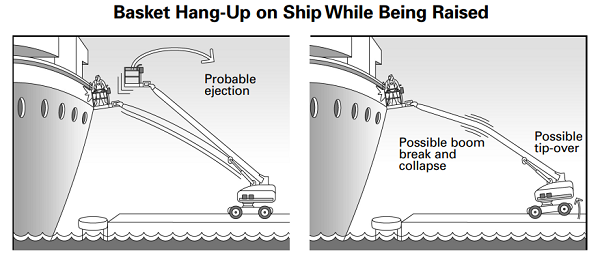

- If the lift gets snagged on something or lines, it could cause an ejection when it breaks free.

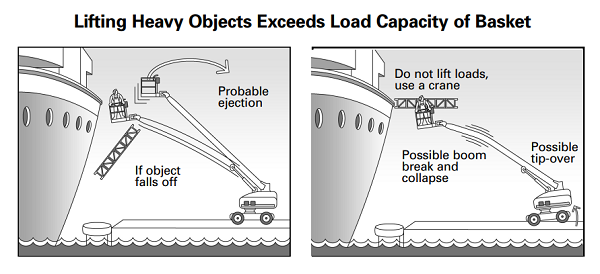

- Don’t use an aerial lift to lift, push, or move objects. That’s a recipe for collapse, tip-over, or ejection.

- Don’t exceed the load capacity with the combined weight of the worker, tools, and materials. Too much weight can lead to collapse or tip-over.

- The lift capacity drops when it’s not level, tire pressure is low, or the outriggers aren’t fully extended – conditions that can cause a tip-over.

- Half of all fatal falls from aerial lifts happen when workers aren’t tied off. One poor worker was ejected 80 feet from an aerial lift.

- Improper setup, operation, or exceeding weight capacity are responsible for twice as many aerial lift fatal falls as mechanical failure.

In conclusion, ensuring the safety of workers during aerial lift operations in shipyards and boatyards is crucial. Employers must prioritize well-maintained equipment, proper supervision, training, and fall protection measures. By following safe work practices, being aware of potential hazards, and never cutting corners when it comes to safety devices or procedures, we can significantly reduce the risk of injuries and fatalities. Remember, it’s always better to take the time to do it right than to suffer the consequences of a preventable accident.

References