Introduction

The handling, storage, and disposal of hazardous waste presents significant safety and health hazards for workers. To address this issue, the Occupational Safety and Health Administration (OSHA) established the Hazardous Waste Operations and Emergency Response (HAZWOPER) standard. This article provides an in-depth look at HAZWOPER and how it aims to protect employees in hazardous materials handling operations.

HAZWOPER Coverage and Requirements

HAZWOPER covers three main types of hazardous material handling operations:

- Hazardous waste site cleanup (e.g. Superfund sites)

- Operations at Treatment, Storage and Disposal (TSD) facilities regulated under RCRA

- Emergency response to hazardous substance releases

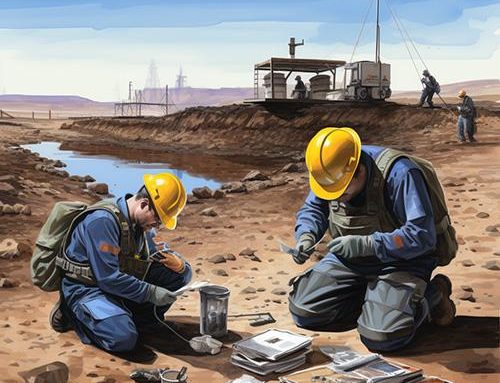

Hazardous Waste Site Cleanup Requirements

For hazardous waste site cleanups, HAZWOPER establishes extensive requirements for site safety, including:

- Developing a written safety and health program covering organizational structure, workplans, training, medical surveillance etc.

- Conducting a site characterization to identify hazards and determine necessary controls

- Creating a health and safety plan (HASP) analyzing tasks, selecting PPE, addressing exposure monitoring, decontamination, emergency response etc.

- Implementing a 24-40 hour initial training program for site workers and supervisors, with 8 hours of annual refresher training

- Providing medical examinations and consultations for exposed workers

Additionally, HAZWOPER includes requirements related to handling drums and containers, decontamination procedures, emergency response plans, sanitation and more at waste sites.

TSD Facility Requirements

At RCRA-regulated Treatment, Storage and Disposal facilities, HAZWOPER mandates:

- Developing a written safety and health program for hazardous waste operations

- Establishing a hazard communication program for “non-waste” hazardous chemicals

- Addressing decontamination, medical surveillance, material handling procedures

- Providing 24 hours initial and 8 hours annual refresher training for TSD workers

- Creating emergency response plans or relying on existing RCRA contingency plans

Emergency Response Requirements

For emergency response, HAZWOPER requires development of an emergency response plan based on potential worst-case release scenarios. It also establishes a structured Incident Command System for coordinating response.

Importantly, HAZWOPER institutes a scale of training levels from First Responder Awareness to Hazardous Materials Specialist based on an employee’s expected role during an emergency. For example, an employee responsible for notification would require awareness level training, while specialist-level training is mandated for providing technical guidance on scene.

Medical evaluations, use of proper PPE, and procedures for post-emergency cleanup operations are also addressed.

Additional Aspects of the Standard

Beyond worksite-specific requirements, HAZWOPER also incorporates provisions related to:

- Recordkeeping for exposure/medical data

- Interfacing with OSHA’s Hazard Communication Standard in regards to community right-to-know about chemical hazards

- Potential overlap with Bloodborne Pathogens standard during cleanups or emergency response involving biological agents

- Need to coordinate HAZWOPER program with other OSHA standards covering confined spaces, respiratory protection etc.

OSHA Assistance Available

OSHA offers various resources to aid organizations including small businesses in understanding and meeting HAZWOPER obligations:

- Confidential consultation services to help employers establish safety programs

- On-site training courses focused on HAZWOPER/hazardous materials offered nationwide

- Voluntary Protection Programs for companies that demonstrate exemplary safety achievement

Additionally, OSHA provides useful online tools, publications, videos, outreach, education and technical assistance on hazardous waste handling.

Leveraging these resources and diligently adhering to HAZWOPER requirements enables improved protection for personnel working with hazardous materials. The standard has had a measurable impact in limiting injuries, illnesses and exposures among affected workers nationwide.