Introduction

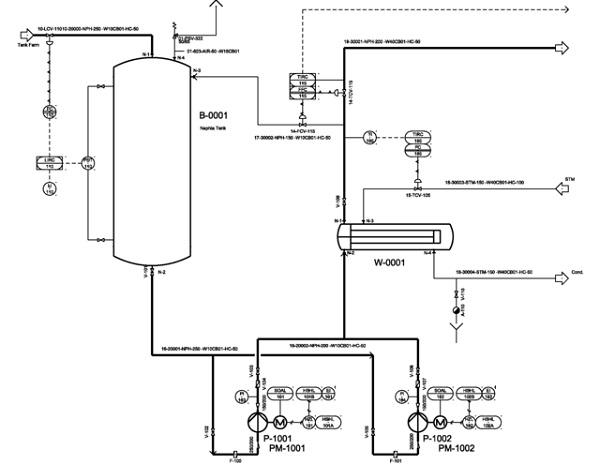

In the process industry, accurate and detailed documentation is paramount for the safe and efficient operation of plants and facilities. Since their inception during the early stages of industrialization, one of the key tools used for this purpose is the Piping and Instrumentation Diagram (P&ID). P&IDs are graphical representations of the process flow, equipment, instrumentation, and control systems in a facility. Evolving over time, these diagrams have become indispensable in today’s complex industrial landscapes. They provide a visual representation of the intricate interrelationships between different components and help in understanding how the process operates, facilitating effective planning, design, and safety implementations.

P&ID Symbols and Notation

P&IDs use standard symbols and notation to represent various equipment, piping, valves, and instrumentation. Governed by international standards such as ANSI/ISA-5.1-2009 and ISO 14617, these symbols are universally recognized and ensure clear communication across different disciplines and organizations. Some common symbols used in P&IDs include:

- Equipment symbols: Representing different types of process equipment such as pumps, compressors, heat exchangers, reactors, and tanks, each equipment symbol has a unique shape and identifier. This helps in identifying the type and function of the equipment in line with established industry standards.

- Piping symbols: Piping symbols represent various types of pipes, such as straight pipes, bends, reducers, and valves. They also indicate the direction of flow and the material being transported. Standardized according to specific guidelines, piping symbols are essential for understanding the layout and connectivity of the piping system.

- Valve symbols: Valve symbols represent different types of valves, such as gate valves, globe valves, check valves, and control valves. They indicate the function and operation of the valve, such as open, closed, or throttling. Following universal recognition, valve symbols play a crucial role in understanding the control and regulation of the process.

- Instrumentation symbols: Instrumentation symbols represent various instruments and sensors used for measuring and controlling process parameters. These symbols, aligned with common industry practices, include pressure gauges, flow meters, level indicators, temperature sensors, and control devices. Instrumentation symbols provide valuable information on the monitoring and control of the process and contribute to maintaining a cohesive understanding across various industry players.

Reading and Interpreting P&IDs

Interpreting P&IDs requires a thorough understanding of the symbols and notation used, as well as insight into the specific process represented. Here’s a guide to assist you in navigating P&ID diagrams:

- Tag numbers: Every component in a P&ID has a unique tag number or identifier. These tag numbers are essential for referencing specific components in the process, aiding in design, troubleshooting, and maintenance tasks. Familiarizing yourself with these numbers and their meanings can provide insights into the relationships between different components.

- Device locations: P&IDs detail the physical locations of devices and equipment within the plant. This information is pivotal for various operational aspects, such as maintenance, troubleshooting, and safety. Locations can be conveyed through grid coordinates, elevation details, or specific areas within the facility.

- Piping connections: Representing the links between different equipment and piping, P&IDs illustrate the flow of materials or signals between components. Understanding the direction of flow, the type of material being transported, and any included valves or control devices is fundamental for interpreting the system’s design and function.

Creating P&ID Diagrams

Creating P&ID diagrams involves a detailed and precise approach that adheres to industry standards. Here’s a guide for crafting accurate and comprehensive P&ID diagrams:

- Gather Information: Obtain all relevant data about the process, such as equipment specifications, piping layouts, control system insights, and instrument datasheets. This foundation sets the stage for an accurate diagram.

- Identify Components: List all the elements that will be featured in the P&ID, including equipment, piping, valves, instrumentation, and control mechanisms.

- Define Symbols and Notation: Engage with standard symbols and notation consistent with industry norms, ensuring that your diagram communicates effectively across various stakeholders.

- Layout the Diagram: Sketch the overall design, including major equipment and piping connections. Utilize software tools specifically designed for P&ID creation to enhance accuracy and facilitate editing.

- Add Details: Incorporate additional information like instrument tags, valve tags, pipe sizes, and control loops. Ensure that the connections and relationships between components are represented clearly.

- Review and Revise: Collaborate with stakeholders and subject matter experts to review the diagram for clarity, consistency, and precision. Make any necessary revisions to ensure the diagram reflects the process accurately.

P&ID Examples and Applications

P&IDs are instrumental across various industries, and their applications are diverse. Here’s how P&IDs function in different sectors:

- Oil and Gas Industry: Within oil and gas facilities, P&IDs facilitate the visualization of crude oil, natural gas, and refined product flows. They support understanding the process of extraction, refining, and distribution.

- Chemical Industry: In chemical plants, P&IDs depict complex processes in the production of chemicals, offering insights into reaction kinetics, heat transfer, and mass transfer in various stages of manufacturing.

- Power Generation: In power plants, P&IDs represent the flow of steam, water, and fuel, contributing to understanding the operation of essential components like boilers, turbines, condensers, and other power generation machinery.

- These examples illustrate the indispensable role that P&IDs play in industrial processes. By offering a clear, graphical representation of complex systems, P&IDs contribute to efficiency, safety, and effectiveness across different industrial applications.

P&ID Standards and Guidelines

Compliance with P&ID standards and guidelines is vital for maintaining uniformity, lucidity, and precision in the design. Industry-recognized standards include:

- ANSI/ISA-5.1-2009: Guidelines for P&ID preparation, encompassing symbols, abbreviations, and identification tags.

- ISO 14617: A comprehensive set of graphical symbols for use in P&IDs and other technical drawings.

- ASME B31.3: Directives for the design and construction of process piping systems, with focus on the layout and portrayal of piping in P&IDs.

- Adhering to these standards ensures that P&IDs are prepared in line with industry norms, facilitating effective communication and operational excellence.

Tips for Effective P&ID Design

Creating clear and accurate P&ID diagrams requires meticulous attention to detail. Here are some insights for effective design:

- Clarity: Employ transparent and concise symbols, notation, and labels. Refrain from overloading the diagram and utilize color or shading to distinguish different types of equipment or systems.

- Consistency: Uphold uniformity in symbols, notation, and layout throughout the diagram. Employ a standardized template and style guide to maintain harmony across different P&IDs.

- Accuracy: Scrutinize the precision of tag numbers, specifications, and connections. Verify that the P&ID diagram faithfully represents the actual process layout and operation.

Common Mistakes

Common mistakes to avoid when creating P&ID diagrams include:

- Inaccurate or incomplete representation of the process: Ensure that the P&ID accurately represents the actual process, equipment, piping, and instrumentation.

- Involving process owners, operators, and experts in the P&ID creation and validation can help prevent this mistake.

- Ignoring practical and physical limitations: When designing a P&ID, consider the real-world constraints of the process, equipment, and piping systems. This helps to create a more realistic and functional diagram.

- Inconsistency in symbols and notation: Use standardized symbols and notation throughout the P&ID to ensure clear communication and understanding across

- different disciplines and organizations.

- Not updating and revising P&IDs: Regularly review and update P&IDs to reflect any changes or improvements in the process. This helps to maintain the accuracy and relevance of the diagrams.

- Overlooking safety features: Ensure that safety features, such as safety valves and interlocks, are correctly represented in the P&ID to avoid potential hazards and operational issues.

- By being aware of these common mistakes and taking steps to avoid them, you can create more accurate and effective P&ID diagrams for your projects.

Conclusion

P&IDs serve as a linchpin in the process industry, offering visual insights into process flow, equipment, and control systems. Mastering the reading, interpretation, and creation of P&ID diagrams is vital for engineers, operators, and maintenance staff. Embracing the guidelines, standards, and best practices elucidated in this article empowers professionals to leverage P&IDs effectively, thereby fostering safe and efficient operation of plants and facilities. By investing in a deep understanding of P&IDs, industries can enhance their process control, safety, and overall efficiency.

Sources:

- Automation Forum: Basics of P&ID (piping and instrumentation diagram)

- Lucidchart: P&ID Symbols and Notation

- Engineering Toolbox: P&ID – Piping and Instrumentation Diagram

- RealPars: How to Read a P&ID? (Piping & Instrumentation Diagram)

- Lucidchart: P&ID Examples

- EdrawMax Online: P&ID Symbols and Meanings

- Wikipedia: Piping and instrumentation diagram

- AutomationForum: Reading and Interpreting of Piping and Instrumentation Diagram

- Vista Projects: 363 Common P&ID Symbols: An Engineer’s Library