Fluorescent bulbs have long been a popular choice for both residential and commercial lighting due to their energy efficiency and longevity. However, these bulbs contain mercury, a toxic heavy metal that poses significant health risks if not handled correctly. This article offers an in-depth exploration of the safety aspects of mercury exposure from fluorescent bulbs, providing a comprehensive guide for occupational health and safety professionals, employers, and employees alike.

Understanding Fluorescent Bulbs and Mercury

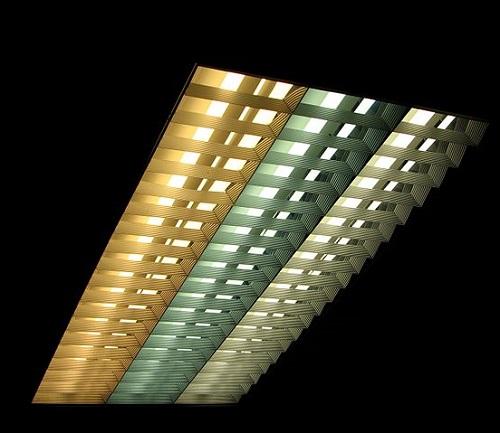

Fluorescent bulbs operate by passing an electric current through a gas—typically a mixture of argon and mercury vapor—inside a glass tube. The electric current excites the mercury vapor, which emits ultraviolet light. This ultraviolet light then interacts with the phosphor coating inside the bulb, resulting in the production of visible light.

The Role of Mercury in Fluorescent Bulbs

Mercury is a crucial component in the operation of fluorescent bulbs, but its presence raises serious safety concerns. Each standard fluorescent bulb contains approximately 5 to 15 milligrams of mercury, depending on the type and manufacturer. Although this amount may seem minimal, it can lead to significant health risks if the bulbs break or are improperly disposed of.

Health Risks Associated with Mercury Exposure

Understanding the health risks associated with mercury exposure is vital to ensuring occupational safety.

Acute vs. Chronic Exposure

Acute Exposure: This type of exposure occurs when an individual is confronted with a large amount of mercury in a short timeframe. Symptoms may include respiratory distress, cough, headaches, dizziness, and severe fatigue. For example, a worker who accidentally breaks several fluorescent bulbs in a poorly ventilated area may inhale mercury vapor, leading to acute health issues.

Chronic Exposure: Chronic exposure refers to long-term exposure to lower levels of mercury, often seen in workplaces where fluorescent bulbs are frequently handled. This type of exposure can lead to serious health problems, including neurological damage, kidney dysfunction, cognitive impairments, and immune system suppression. Research has shown that workers in recycling plants handling broken bulbs exhibit elevated mercury levels in their systems, underscoring the need for strict safety protocols.

Safety Protocols for Handling Fluorescent Bulbs

Given the potential hazards, implementing safety protocols for handling fluorescent bulbs in occupational settings is essential.

Training and Awareness

Employers must provide comprehensive training to employees regarding the risks associated with mercury exposure and the proper handling of fluorescent bulbs. This training should encompass:

- Identifying hazards: Employees should be educated on recognizing broken bulbs and understanding the associated risks of mercury exposure.

- Safe handling procedures: Detailed guidelines for transporting, storing, and disposing of fluorescent bulbs should be emphasized, ensuring that all employees understand the importance of these practices.

- Emergency response: Workers must be trained on how to respond effectively in case of a bulb breakage, including evacuation procedures and proper cleanup methods.

Personal Protective Equipment (PPE)

The use of PPE is critical when handling fluorescent bulbs. Essential gear includes:

- Gloves: Nitrile or rubber gloves can help prevent skin contact with mercury, which can occur if the bulb breaks.

- Safety goggles: These protect the eyes from potential glass shards and prevent inhalation of mercury vapor.

- Respirators: In environments where breakage is frequent, a respirator with a HEPA filter may be necessary to avoid inhaling harmful particles.

Disposal and Recycling of Fluorescent Bulbs

Proper disposal and recycling methods are essential to minimize mercury exposure and environmental impact.

Regulations and Guidelines

Many countries have established regulations governing the disposal of fluorescent bulbs due to their mercury content. In the U.S., the Resource Conservation and Recovery Act (RCRA) classifies spent fluorescent bulbs as hazardous waste. Businesses must adhere to local regulations, which often include:

- Labeling: Clearly marking containers that hold used bulbs to prevent accidental breakage and ensure proper handling.

- Transportation: Following specific protocols when transporting bulbs to recycling facilities to minimize risks during transit.

- Documentation: Keeping accurate records of disposal and recycling efforts to ensure compliance with local and federal regulations.

Recycling Options

Recycling fluorescent bulbs can significantly mitigate mercury exposure risks. Many municipalities and private companies offer recycling programs.

- Retail drop-off: Some retailers operate take-back programs where consumers can return used bulbs for safe disposal.

- Dedicated recycling facilities: Many cities have established facilities specializing in handling hazardous waste, including fluorescent bulbs. These facilities ensure that mercury is safely contained and does not pose a risk to public health or the environment.

Addressing Common Concerns

As concerns about mercury exposure continue to rise, many questions may arise regarding fluorescent bulbs and safety protocols.

What Should You Do If a Bulb Breaks?

In the event of a breakage, it is crucial to follow specific steps to minimize exposure:

- Evacuate the area: Ensure that everyone leaves the vicinity to avoid inhaling mercury vapors.

- Ventilate the space: Open windows and doors to allow fresh air to circulate and disperse any potential fumes.

- Clean up carefully: Use stiff paper or cardboard to gather the larger pieces of glass, and use duct tape to pick up smaller shards and powder. A vacuum should not be used, as it may spread mercury particles.

- Dispose of waste properly: Place all broken pieces and cleanup materials in a sealed plastic bag and follow local guidelines for hazardous waste disposal.

Are There Alternatives to Fluorescent Bulbs?

Given the health concerns associated with mercury, many individuals and businesses are exploring alternatives.

- LED bulbs: Light Emitting Diodes (LEDs) are increasingly popular due to their energy efficiency and lack of hazardous materials. Unlike fluorescent bulbs, they do not contain mercury, making them a safer option.

- Compact fluorescent lamps (CFLs): While these still contain mercury, they generally have a lower mercury content compared to traditional fluorescent tubes. However, proper handling and disposal are still necessary.

Conclusion: Promoting Safety in the Workplace

Fluorescent bulbs, while energy-efficient, pose significant health risks due to their mercury content. Understanding these risks and implementing proper safety protocols are crucial for protecting workers and the environment. Employers must equip their staff with appropriate training, safety measures, and awareness to prevent mercury exposure and foster a culture of workplace safety. As regulations evolve, staying informed about safe handling and disposal practices is not just a legal requirement, but a moral imperative.

Looking ahead, the focus should be on developing safer lighting alternatives and improving occupational health practices. Research into mercury-free technologies and adoption of global best practices in fluorescent bulb handling will be key to reducing exposure risks. As we strive for more sustainable and health-conscious workplaces, it’s essential to go beyond mere compliance and actively seek innovative solutions. By prioritizing worker safety and environmental protection, we can pave the way for a brighter, safer future in lighting technology and occupational health.