Workplace injuries and illnesses can be devastating, both to workers and companies. However, many of these incidents can be prevented through proper safety practices and awareness. This article will explore some of the essential elements of workplace safety, including developing a safety mindset, maintaining clean and hazard-free work areas, properly using tools and equipment, safely handling chemicals, and wearing appropriate personal protective equipment (PPE). Implementing these safety fundamentals can go a long way in protecting yourself, your coworkers, and your company.

Developing a Safety Mindset

The first and possibly most important step in accident prevention is cultivating a positive safety attitude. You need to build good safety habits and behaviors into your work, rather than treating them as an afterthought. Key aspects of a safety mindset include:

- Knowing your abilities and limitations. Don’t take on tasks you aren’t trained for or push yourself beyond healthy physical or mental limits.

- Maintaining self-control and avoiding frustration. Don’t let yourself become angry or rushed on the job in ways that lead to unsafe choices.

- Recognizing the need for breaks. Listen to your body and take short breaks as needed to avoid fatigue.

- Staying focused. Don’t let your mind wander or go into “autopilot” during repetitive tasks.

- Not taking unsafe shortcuts. Never bypass safety rules or remove machine guards to try to work faster.

- Understanding the reasons behind safety rules. Following protocols just because they are the rules leads to poor compliance. Know why the rules exist.

- Speaking up about hazards. Report any safety issues you notice so they can be addressed before they cause harm.

While developing a safety mindset takes effort, it will quickly become second nature. A constant safety-first attitude will benefit you throughout your career.

Maintaining Clean and Orderly Work Areas

Cluttered, messy work spaces are one of the major causes of workplace accidents. Trip hazards, blocked emergency exits, and obscured hazards lurk in dirty and disorganized work areas. Some of the main housekeeping efforts that reduce accidents include:

- Cleaning up spills immediately to prevent slips. Mark wet areas with warning signs.

- Keeping walkways and exit routes clear. Don’t store materials or equipment in hallways, aisles, or stairwells even temporarily.

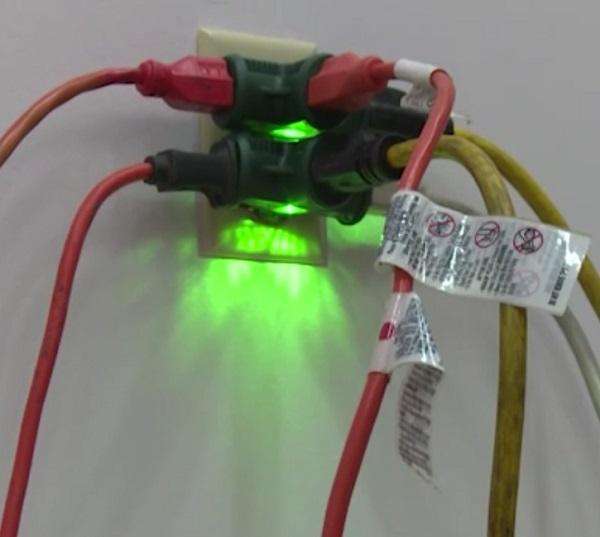

- Securing extension cords and hoses out of high-traffic areas. Tape them down if needed.

- Closing drawers and cabinet doors when not in use to prevent tripping hazards.

- Picking up small objects like screws or paper clips that could cause slips.

- Properly storing supplies, tools, and equipment when not in use.

- Disposing of excess clutter and waste frequently.

- Marking slippery areas and safety paths for heavy equipment.

- Reporting lighting issues and blocked sight lines that obscure hazards.

- Daily cleaning and inspection to maintain safe conditions.

A clean workplace removes hazards before they can cause injuries. While working, be mindful of creating new hazards and proactively clean as you go. A tidy workplace is a safer workplace.

Using Tools and Equipment Safely

Power tools and industrial equipment account for many traumatic workplace injuries each year. While machines and tools are necessary for work, they can be hazardous if not treated with proper caution and respect. Key ways to safely use tools and equipment include:

- Selecting the right tool for the task and using it as designed. Improvising leads to more accidents.

- Inspecting tools prior to use to identify any damage or defects. Remove damaged tools from service.

- Operating tools according to manufacturer instructions. Don’t take shortcuts.

- Keeping blades and bits sharp. Dull edges require extra unsafe force to function.

- Maintaining machine guards. Never remove or tamper with safety guards.

-Performing maintenance with machines fully powered down and locked-out.

- Using sturdy stepladders instead of chairs or boxes to reach high areas.

- Lifting and moving tools and materials safely by bending knees, getting help, and using dollies. Don’t lift more than you can handle alone.

- Storing tools in their proper places and cleaning them prior to storage.

Rushed or improper tool use causes many hand and eye injuries. Taking the time to use tools correctly goes a long way in preventing trips to the emergency room.

Handling Chemicals Safely

Chemicals pose both acute and long-term health hazards if not properly handled. Mixing incompatible chemicals can cause dangerous reactions. Key aspects of safe chemical handling include:

- Reading all chemical container labels and SDS sheets prior to use. Follow their directions.

- Storing chemicals according to compatibility, temperature, ventilation, and other SDS recommendations.

- Using PPE indicated on SDS sheets such as gloves, goggles, face shields, and respirators.

- Providing adequate ventilation when working with chemicals prone to hazardous fumes.

- Knowing emergency procedures in case of spills or chemical releases.

- Cleaning up spills completely using procedures outlined on SDS sheets.

- Disposing of chemicals per SDS and workplace guidelines. Many require special hazardous waste procedures.

- Keeping food and beverages out of all chemical storage and use areas to prevent contamination.

- Reporting damaged or leaking chemical containers immediately for proper disposal.

- Restricting access to chemical storage rooms to authorized personnel only.

Understanding a chemical’s hazards and using proper handling techniques are critical to avoiding chemical accidents and exposures. Don’t rush when working with chemicals and ask for help if ever unsure.

Wearing Proper PPE

Personal protective equipment acts as a last line of defense when engineering controls and safe work practices cannot fully eliminate a hazard. Examples of common PPE include:

- Safety glasses, goggles, face shields – Protect eyes and face from flying debris, chemicals, sparks, etc. Match to anticipated hazards.

- Hearing protection – Reduces potential for hearing damage in loud environments.

- Hard hats – Prevent head injuries from falling or flying objects. Required in construction and many industrial settings.

- Work gloves – Protect hands from sharp edges, hot items, chemicals, electricity, and more. Choose gloves designed specifically for anticipated exposure.

- Safety shoes – Steel toes and slip-resistant soles prevent foot injuries. Specialty shoes may be needed for some hazards.

- Respirators and masks – Protect workers from breathing in hazardous dusts, fumes, and chemicals. Must be properly selected and fitted.

- Protective clothing – Aprons, suits, and full-body coverings shield skin from chemical splashes or extreme heat/cold.

- Fall protection – Harnesses and anchorage systems catch workers and prevent serious falls when working at height.

- Flame resistant clothing – Firefighting gear, welding leathers, and other specialized items prevent burns.

PPE becomes useless if workers fail to use it correctly. Train employees on proper

PPE selection, inspection, wearing, cleaning, and storage. Set policies on what

PPE must be worn for typical tasks. Safety equipment can’t protect you if it stays in storage.

Conclusion

While workplace hazards will always exist, implementing solid safety practices greatly reduces the risks. Developing a safety mindset, maintaining clean workspaces, properly handling equipment and chemicals, and using protective gear are fundamental to protecting yourself and your coworkers from harm. Dedicate yourself to implementing these essential safety practices at your workplace. The results will speak for themselves.

With this understanding of the critical elements of workplace safety, it’s time to take a proactive step towards implementing these practices. This is where our “Safety Housekeeping and Accident Prevention” online training program comes into play. Designed to enhance safety and efficiency in your workplace, our program offers a comprehensive approach to safety training, ensuring that your team not only understands but also applies these crucial safety principles in their daily work life.

Welcome to the next level of workplace safety and efficiency with Our “Safety Housekeeping and Accident Prevention” online training program. This comprehensive course is your ultimate tool to foster a culture of safety and vigilance in your work environment.

Cultivate a Safety-First Mindset

Understanding that the foundation of a safe workplace starts with the mindset of its employees, Our course is expertly designed to instill a robust “safety attitude”. This program doesn’t just inform; it transforms your employees’ approach to safety, making it an integral part of their daily routine.

A Tailored Safety Curriculum

Our interactive, full-length courses and Micro-Learning modules cover essential topics vital for maintaining a safe work environment:

- Developing and nurturing a proactive safety attitude.

- Effective maintenance and organization of the work environment.

- Safe and responsible use of tools and equipment.

- Recognizing, storing, and handling hazardous materials.

- Efficient spill cleanup and disposal techniques.

- Comprehensive understanding and use of personal protective equipment.

Micro-Learning for Maximum Impact

In today’s fast-paced world, lengthy training sessions can be challenging. Our Micro-Learning approach breaks down complex safety concepts into concise, engaging 3-5 minute courses. This method ensures better retention and application of safety practices in daily work activities.

Language No Barrier

To ensure no employee is left behind in this crucial training, all our courses and materials are available in both English and Spanish. This inclusive approach guarantees that your diverse workforce is equally equipped with the knowledge they need for a safer workplace.

Beyond Digital Training

We understand that learning styles vary. That’s why Our offers a range of training materials, including DVDs, interactive CD courses, kits, booklets, and more, to complement our online courses. This holistic approach ensures a deep and lasting understanding of safety housekeeping and accident prevention.

Your Safety Training Partner

Choose Our “Safety Housekeeping and Accident Prevention” for an all-encompassing safety training solution. We are committed to helping you build a safer, more aware, and productive work environment.

Experience a demo of Our Online Training System and view a detailed course outline to see how we can transform your workplace safety culture. Let’s join hands in creating a safer tomorrow, today!